News

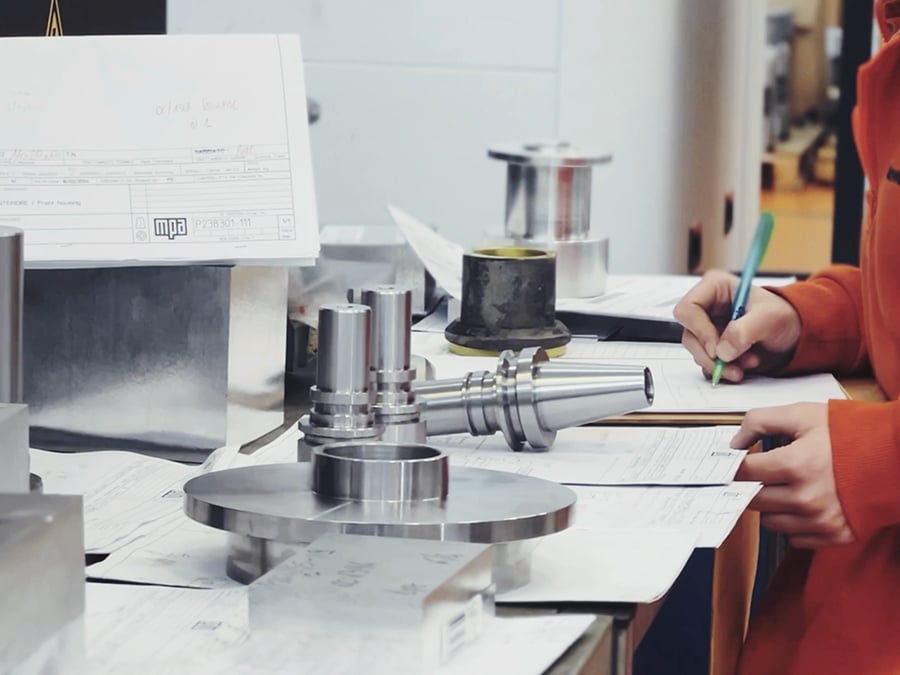

Euroma Group would like to thank MPA for having accepted to take part in a common project aimed at aggregating different historic brands from the machine tool components sector under a single purpose which combines experience and development.

Therefore, it’s with great satisfaction that today our Group can count on the Made in Italy excellence of MPA that has been producing angular heads, multi spindle heads and overgears since more than 45 years.

This collaboration is due to common ethical and entrepreneurial values and to the awareness of preserving brand’s identity together with its personnel and its traditions. In fact, the preservation of all single identities and members is essential for a company.

Therefore, Euroma Group is enthusiastic about taking the chance to cooperate with MPA, knowing that their mutual exchange will enrich all members of the Group.

Following this important goal, in the next future, we hope to enlarge our Group with all Italian brands, whose solution for future challenges is a “combination of important dimension and common ideas”.

Exhibitions

Euroma Group is ready to participate in EMO fair in Hannover, the world exposition dedicated to the metalworking sector that takes place from the 16 th to the 21 st of September 2019.

Lorenzo Di Marco, General Manager of Euroma Group said: “ Besides offering a wide range of exhibitors, EMO Hannover also organizes several events: It’s a very important event for production experts from all over the world. Therefore, we cannot miss it because it is a chance for us to learn more about the latest solutions and the most innovative technologies in the metalworking sector”.

The next edition of EMO, which is well-known as a meeting point for high-ranking tenders and consumers, is expected to be attended by more than 2.200 exhibitors. More than half of them come from countries outside Germany and belong to international companies involved in the industrial automation and in the production of machine tools, components, other tools and software.

Visit us at Pavilion 5 Stand C28

We are looking forward to seeing you!

News

Discover what is behind the scenes of the production process, between industriousness and wit.

Although mechanic is often associated with static characteristics like precision, reliability, durability, the updating process in which it is involved cannot be overlooked.

The world of tool machines is in fact affected by a constant evolution: keeping up with technological progresses and being able to seize the margins of innovation is the key to the realisation of high-performance product of impeccable quality.

In order to be and stay relevant it is important to get involved: make strategic choices, invest in resources and materials, focus mainly on study, preparation and research, hold the necessary foresight to plan a sustainable development, and last but not least, make productive growth match with ethical soundness.

The real strength of a group, even if it is a corporate group, lays in the sharing of values and goals, that is why in Euroma Group there is no business without ethics: the revenue has to be accompanied by social responsibility and environmental protection.

The aspects that have to be balanced in order to operate in the field of machine tools are therefore numerous, so with great commitment and the always required stability Euroma Groups keeps thinking big, starting from the design to the delivery to the customer.

The production of high-precision, reliable, robust items in not enough. The world of tool machines demands a lot more.

In order to satisfy these needs, the inspiration that lies beneath the creative process is essential, as well as a natural tension towards progress and a strong sense of belonging to keep a vast family united.

Because Euroma Group, in the end, is simply that: one and only family, comprised of various companies, many people and numerous products.

In order to get to know it better, we advise you to watch the latest video: view it now!

News

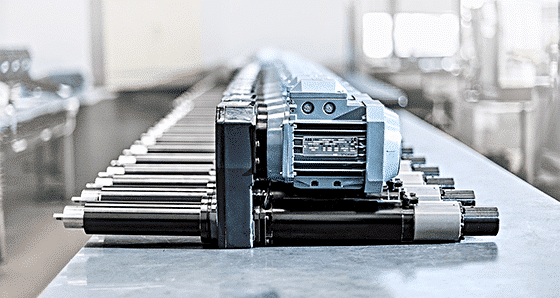

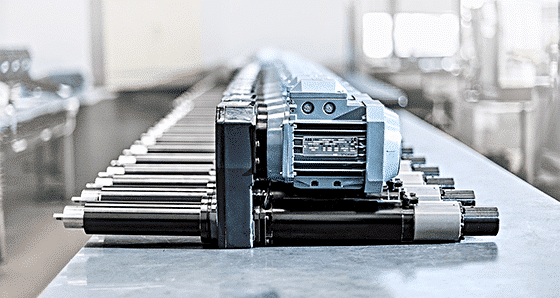

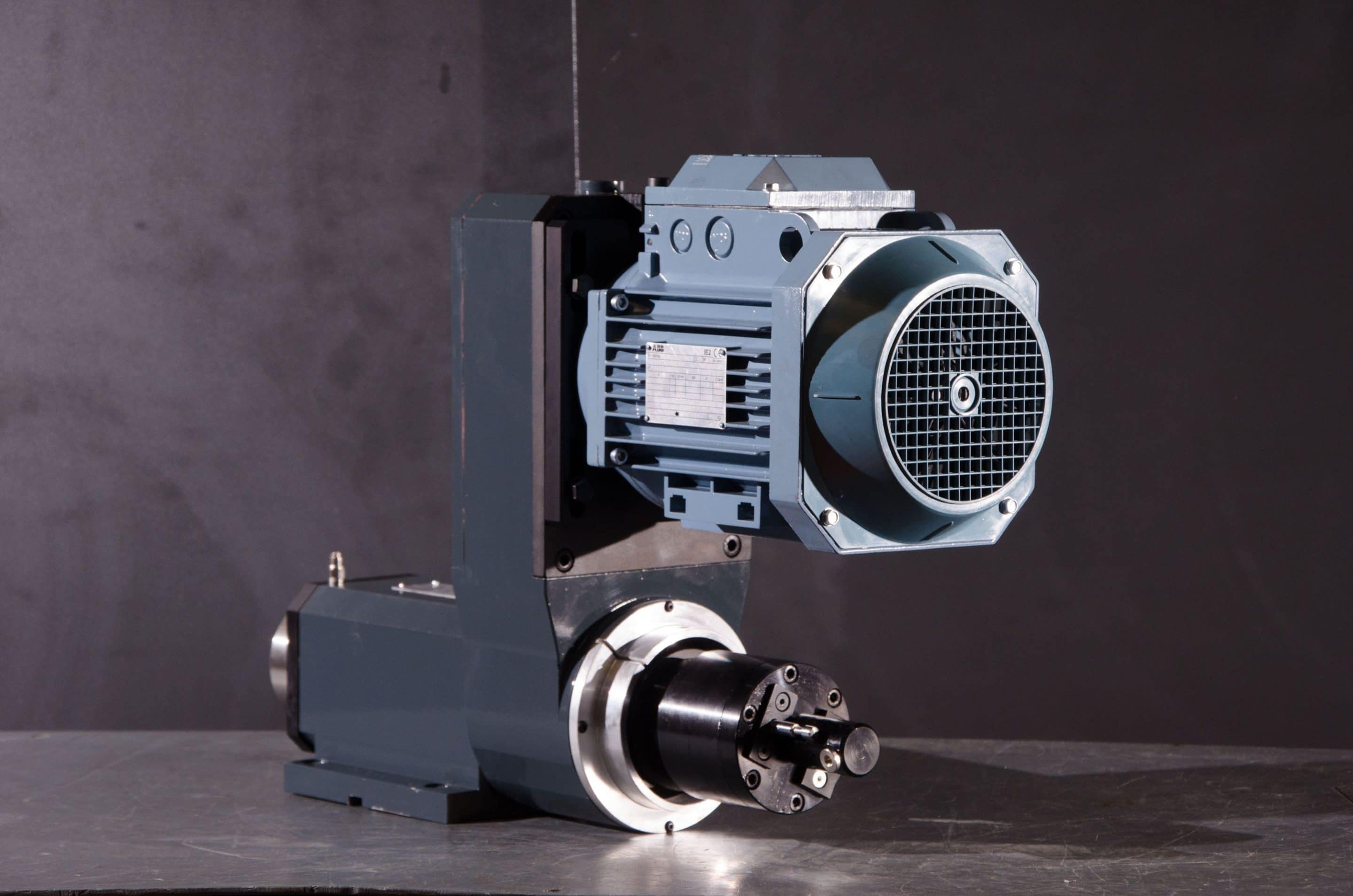

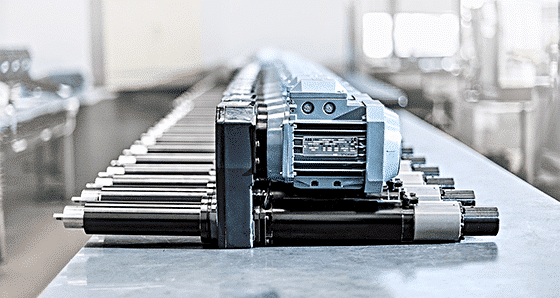

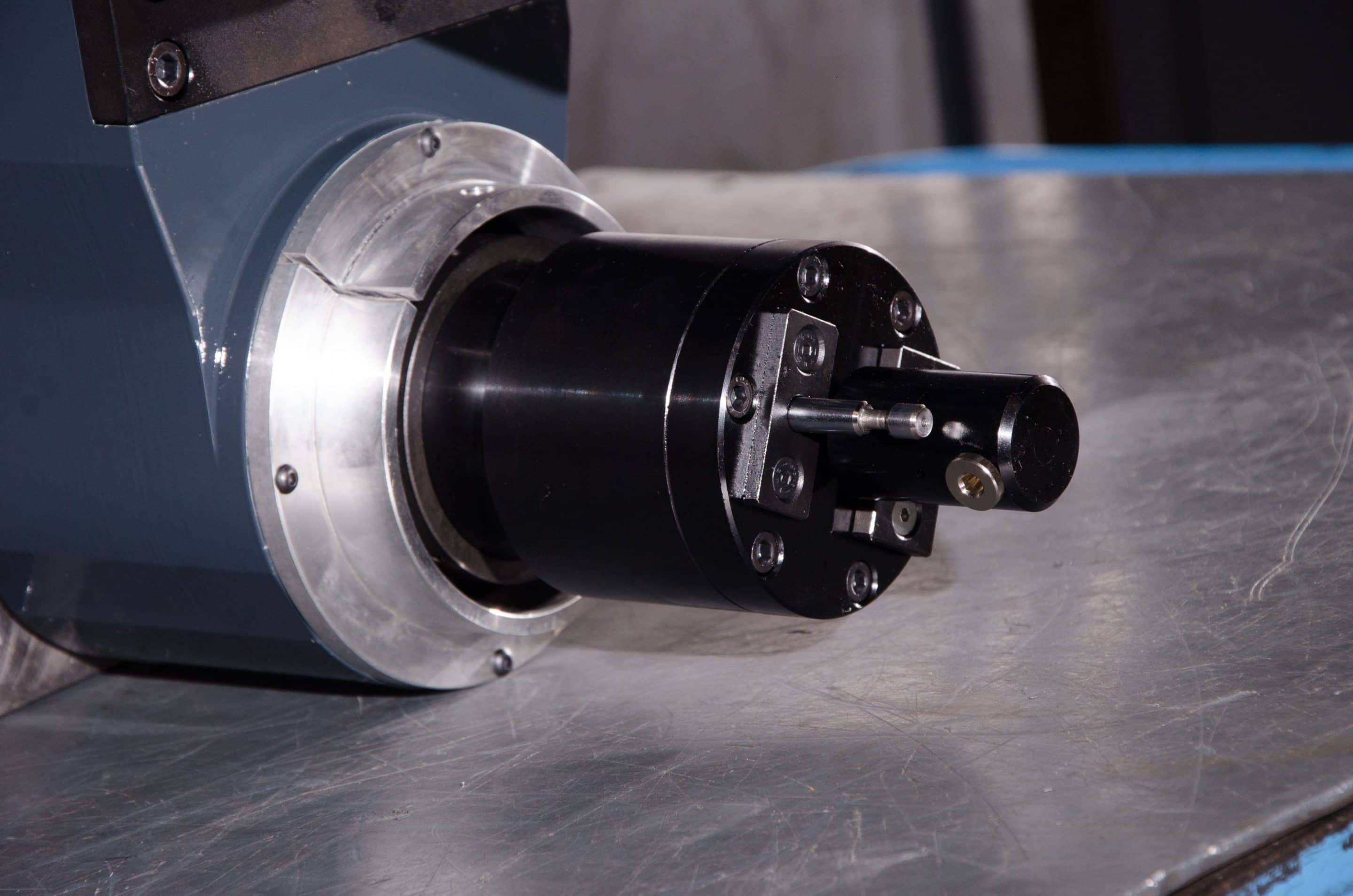

The processing of bars and pipes following the process of cutting gives a valuable productivity advantage.

The mail goal of every firm that wants to optimize its production is to avoid taking back the piece and moving it around the workshop. The workpiece coming from an automatic machine might be put in a dedicated station placed in line with the process and handled on both sides.

Drillmatic machining spindles, matched with the respective slide units with grinded rolling ball are the ideal solution to every processing of bars and pipes’ ends. The rigidity and the positioning accuracy ensure a high reliability over time. The centring of a piece on a lathe, end-trimming, scarfing, fitted screwing-thread and even more, to achieve an unlimited versatility.

Discover our range of machining spindles and CNC slide units.

News

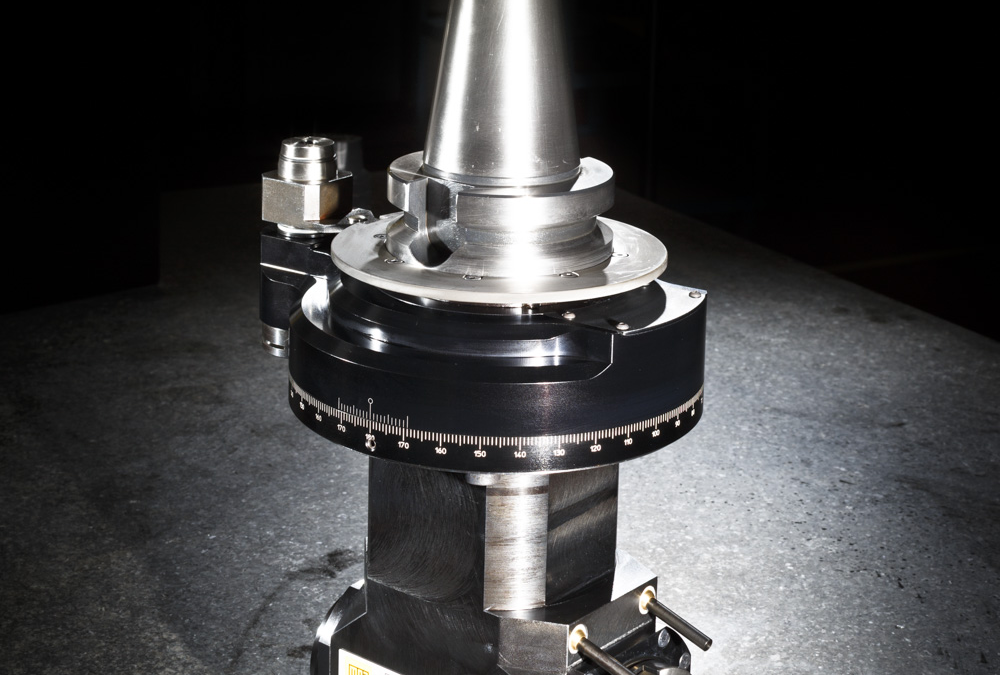

An item becomes an extension of yourself as soon as you forget you are wearing it.

That is what a machining centre provided with MPA angle heads would say, if it could.

In fact, “Slim” Gamma is so slim that it allows the execution of works within small spaces, without ever setting aside an extreme rigidity.

Main technical features here below:

- Integral shank with central shaft in one solid piece.

- Offset design to allow more space for the tool.

- Elastic collet embedded in the head body for the most compact sizes.

- Oblique contact bearings for high cutting speeds

- Small weight and size, suitable for use in tool storage

Download our catalogue and select the most suitable product for your use.

Do not hesitate to contact our technical office.

News

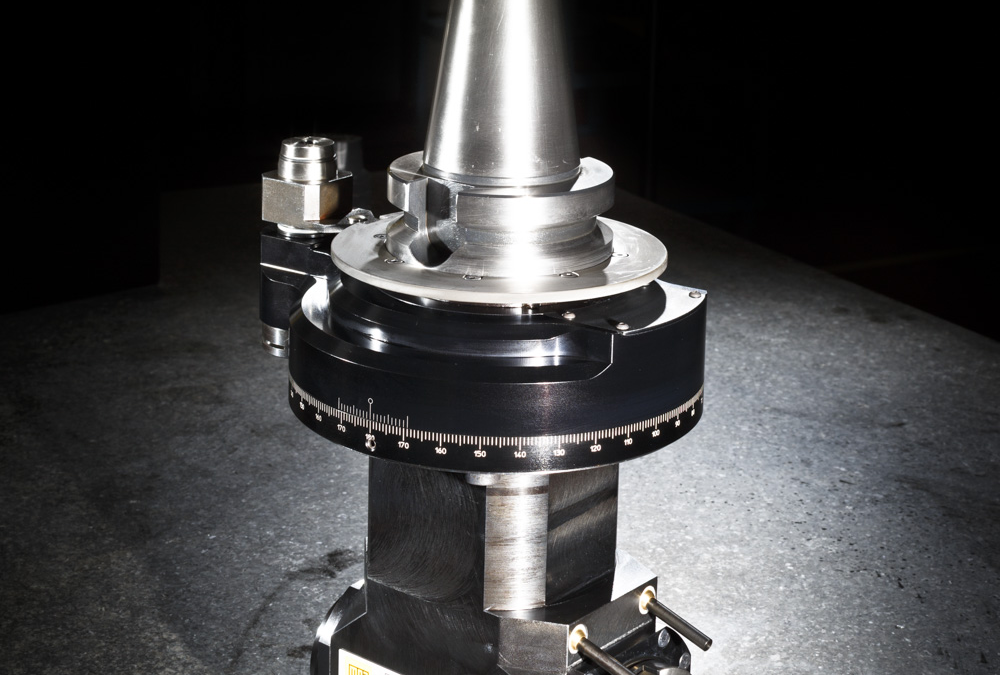

For 45 years we have been increasing the value of your machine tools.

A range that counts more than 130 standard angle heads.

An archive that contains more than 24.000 specialized heads produced for dedicated applications.

With over 45 years’ experience in the world of transfer and traditional machines.

This is MPA.

The time we are in require flexible machine tools, extremely low equipping times, flawless standards and performances.

The wide range of choices that the market offers is surely attractive and full of solutions. But a high-quality machine needs high-quality accessories, and that is where MPA comes into the picture.

MPA is symbol of high quality in the international scene of accessories for machine tools.

Its origins lie in the production of multiple heads with adjustable and fixed centre distance. Later, in the 1980s, with the advent of the first machining centres, MPA focused most of its core business in the design and realisation of a wide range of standard angle heads.

Over time heads have been adapting to the sizes and weights that the market requires, in order to be handled inside tool warehouses, and the variety of it has enlarged thanks to the increasing capacity of the machines to support high-quality and high-performance accessories.

MPA angle heads are available with the classic ISO and HSK shanks of different sizes; every one of them is available with quill clamp, stop-bar pin, anti-rotation system with stiffening pins, passage of the coolant through the tool with low or high pressure, transmission in gear or torque multiplication ratio. Every head undergoes strict quality and size controls before going to the market.

In the catalogue we find “slim” heads, designed to perform small operations in confined spaces, “compact” heads, able to transmit up to 90 Nm torque while maintaining small dimensions, extended heads, angle heads, double-ended heads, off-set heads, heads for heavy duties, adjustable angle heads.

In short, a complete and very wide range of products. Whatever your needs are, our technical staff will be happy to support you towards the best choice.

News

In the beginning, every great success is just a thought

From a sketch on paper to the realization of the complete machine: that is the challenge that Unistand takes up every day. In this case we are talking about a special semi-automatic machine to end-trim and round bars.

The machine is serviced by an infeed chute powered by an operator and can perform four operations in one. This piece, which can be of different diameters and length, is channelled in the engine fixed cradle, where a two-handed pick&place CNC picks it up and brings it to the workstation. After blocking the piece at an adjustable pressure, the hydraulic clamp is moved to the workstation thanks to a controlled axis.

As the bar moves through the two motorized opposite spindles, it gets adequately end-trimmed and then rounded with a special tool, composed of an insert milling cutter and bevel cartridge.

Every axle of the machine is controlled by brushless motors, in order to allow the operator to change format in record time.

The substitution of the tool is extremely quick as well, thanks to the HSK connection, which enables a precise pre-setting, as well as rigidity and high-quality standards of processing.

News

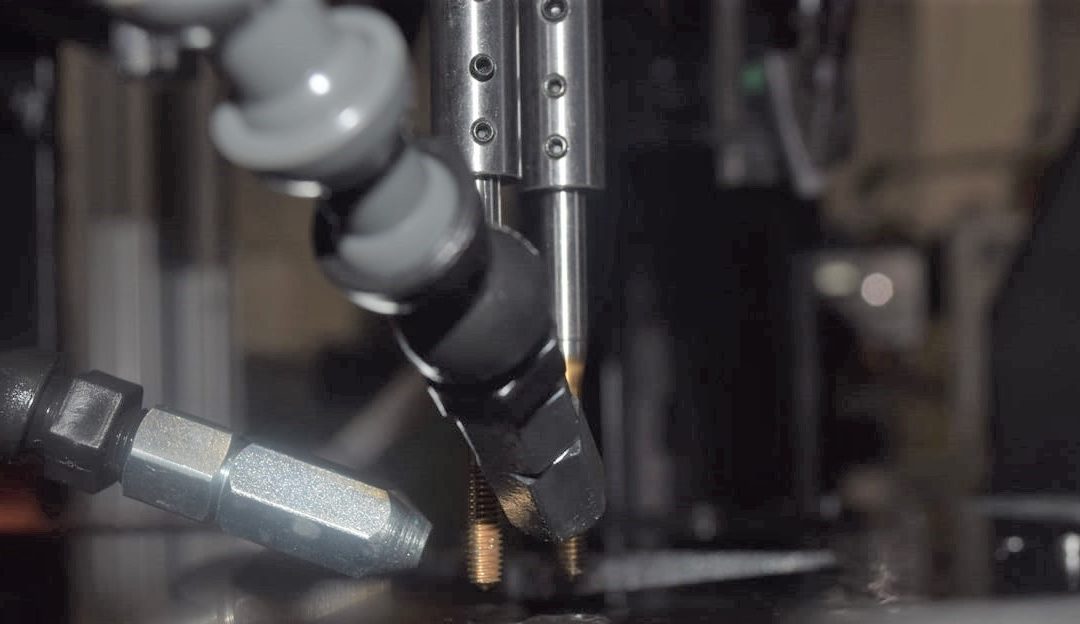

Quill units – Classic and functional design

Electro-pneumatic drilling units Drillmatic by Euroma Group are designed to offer the maximum possible modularity.

Manufacturers of industrial machines and automation can have a wide choice and great adaptability in the design.

The different operating stroke solutions, available for most of the quill unit models, maximize space and avoid the designer looking for complex solutions.

The wide range of available tool holders allows not to use extensions and adapters, which distance the tool from the bearings and tend to generate concentricity errors, consequently causing vibrations and poor processing quality.

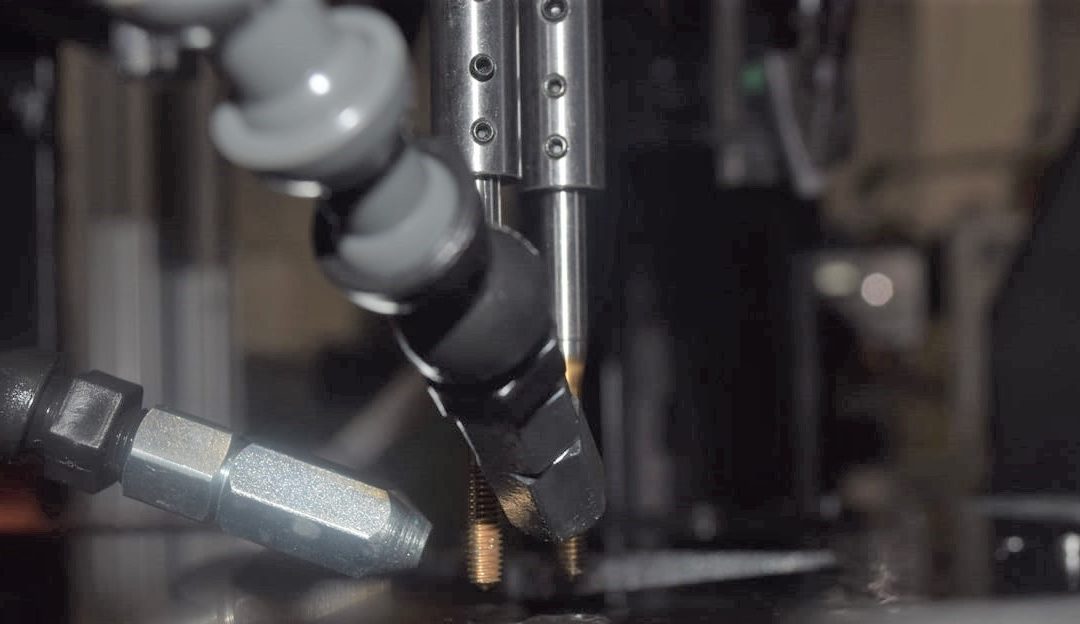

The well-known and recognizable design of the Quill Electro-pneumatic tapping and drilling units Drillmatic by Euroma Group not only allows an extremely modular fixing, but also offers the great advantage of rotating the unit on 360°, thanks to the static support that “embraces” the cylindrical body of the unit.

The Quill units Drillmatic by Euroma Group can be installed both horizontally and vertically and are available with fixed and adjustable supports for mounting on the machine. Furthermore an angular adjustment is made possible by a 360° articulated support.

Besides all units are equipped with fixing for circular transfer machine, that is with front threaded holes.

Quill tapping units Drillmatic by Euroma Group all have a fixed pneumatic rapid approach stroke as an optional for those obstructions that do not allow to work besides the piece to be machined.

Besides the classic quill drilling and tapping units with lead screw, the range also includes the CNC version, with feed by means of ball screw and brushless motor. This type of quill unit enables to perform any type of axial machining and change the working parameters directly from the operator panel. Drilling with chip discharge cycle, drilling with “skip”, to machine tubes, reverse cycle deburring, interpolated tapping: all of these options are easily manageable as the CNC Drillmatic by Euroma Group Quill units are ideally suited to perform them.

Our staff is at your complete disposal for any inquiry, so do not hesitate to contact us.

News

The new way of producing: process control, remote management, instant format change

Transfer with high drilling and roll threading production on metal small parts: Let’s discover all particular features of the transfer machine together with the concept of today’s productivity.

The wheel is turning and turning…

The transfer machine for the production of metal small parts always has to meet all necessary speed, precision, reliability and consistency standards.

But today this isn’t enough: Since human tendency is to go for an even less manual work, the machine needs to be even more independent from operator’s control.

4.0 Industry is the big movie screen where all values, tendencies and diagrams are outlined and made explicit. But, what hides behind it? What is faster than the electricity passing from the control devices to the PLC terminal boards?

The answer to these questions is only one: the innovation willingness.

This is actually the industry sector which is changing and adapting.

Euroma Group took the hard challenge to put its signature on a machine that doesn’t produce only metal small parts every 3 seconds, but that is also able to make two opposite concepts coexist: rigor and flexibility.

From one side, we talk about rigor because each machine’s action is controlled. In fact, all pieces undergo process controls that provide the remote machine supervision with a clear and detailed overview, which, however, doesn’t affect significantly the machine’s flexibility.

For the other side, we talk about flexibility because the format change is extremely fast and easy to handle. In fact,

thanks to the logic in which this machine was conceived, it’s possible to switch from one piece to the other in 30 minutes.

Our staff is at your complete disposal for any further information.

News

It is commonly known that automation, arises from the need to produce a high number of pieces in a short time and mostly with a level of repeatability and tolerance close to perfection.

Human supervision, according to the new philosophy, has to be so significantly reduced that the word "operator" is now only a legacy of the past, since the job of those who hold that role is no longer to operate but “to control”

However, nowadays there are only few sectors that are still lucky enough to have large numbers of parts to be scheduled in production. After the crisis that begun more than a decade ago, there has been a sequence of ups and downs mixed with promises and hints of confidence, forecasts, and hypotheses of trends. However, we haven’t a returned to full production yet.

Automation has adapted and has evolved from being rigid and heavy to being flexible and "minimal". Cast iron bases have turned into aluminum profiles, oil tanks have given way to MQL systems, therefore spaces have necessarily shrunk. Evolution and adaptation in the world of industrialization are generated by the same needs as the evolution of people and follow the same key points of human adaptation to conditions of majeure force. In this case, we also speak about species’ survival and origins’ conservation. In order not to die and not to be invaded, the silent and laborious world made by all that group of small-medium craftsmen and inventors has shaped its ideas over the time to serve something bigger and longer lasting than themselves.

There must be four prerogatives: quality, savings, autonomy and flexibility. The new machine concept must embrace all these concepts and mix them to form something attractive for the market. It must be something that has a value that justifies the purchase and makes it less tragic to predict that an article will change shape in the future, that a center distance will move or that, in the worst cases, will go out of production.

This can happen in any sector because everything evolves. Cars are constantly changing (laws and governments encourage this change, perhaps as an attempt to keep consumerism alive), engines are designed differently, materials change not only in the metalworking sector but also in the appliance and building sector and the list could go on forever.

Especially in the latter case, above all in the production of accessories for windows, components changes are on the agenda. The competition, perhaps among the highest ever, is so high to lead to the implementation of the research aimed at improving and optimizing production costs. Die-cast zamak or cold-pressed steel parts need to be picked up mostly with drilling, threading and screwing operations. The biggest problem for those who produce in this sector is the great variety of components that have similar shape but with significant geometric differences, due to which it isn’t possible combine different pieces in the same production cycle which is therefore defined as “rigid”. This is the reason why the idea of a special machine has been developed , which is consequently rigid by its intrinsic nature but also flexible and quick in format change. Luckily, in the world of aluminum frames, large numbers, even though fragmented, are still there, but each component doesn’t employ a single machine. To make ends meet, therefore, it is necessary to use a single machine which makes it possible to perform a format change quickly, intelligently and can be handled even by an inexperienced operator.

Which are the limits? Those we impose on ourselves. Theoretically, with a machine designed to be flexible, we can work any type of piece and all similar ones. It’s only necessary to establish the number of stations at the start, the structural capabilities of each individual station (power, torque, number of revolutions, etc …)the cycle time and the quality to be reached. Everything else is design.

The replacement of various components to perform the format change is an operation of limited duration, and varies according to the piece to be produced. The operator is facilitated in the operation by fixed references that leave no room for tooling errors.

Once the machine has been equipped for the new production, it is sufficient to recall the piece to be machined from the touch screen. The possibility to use the 4.0 interface also helps the operator by indicating him which the next format changes will be so that the fitter can prepare the components to be replaced in advance.

This machine concept can be applied to any production sector. For any need or evaluation, Euroma Group is at your complete disposal. We’ll be happy to deal with any type of request to give you the most effective solution to your production needs.

News

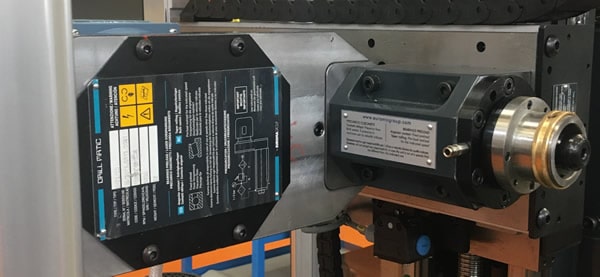

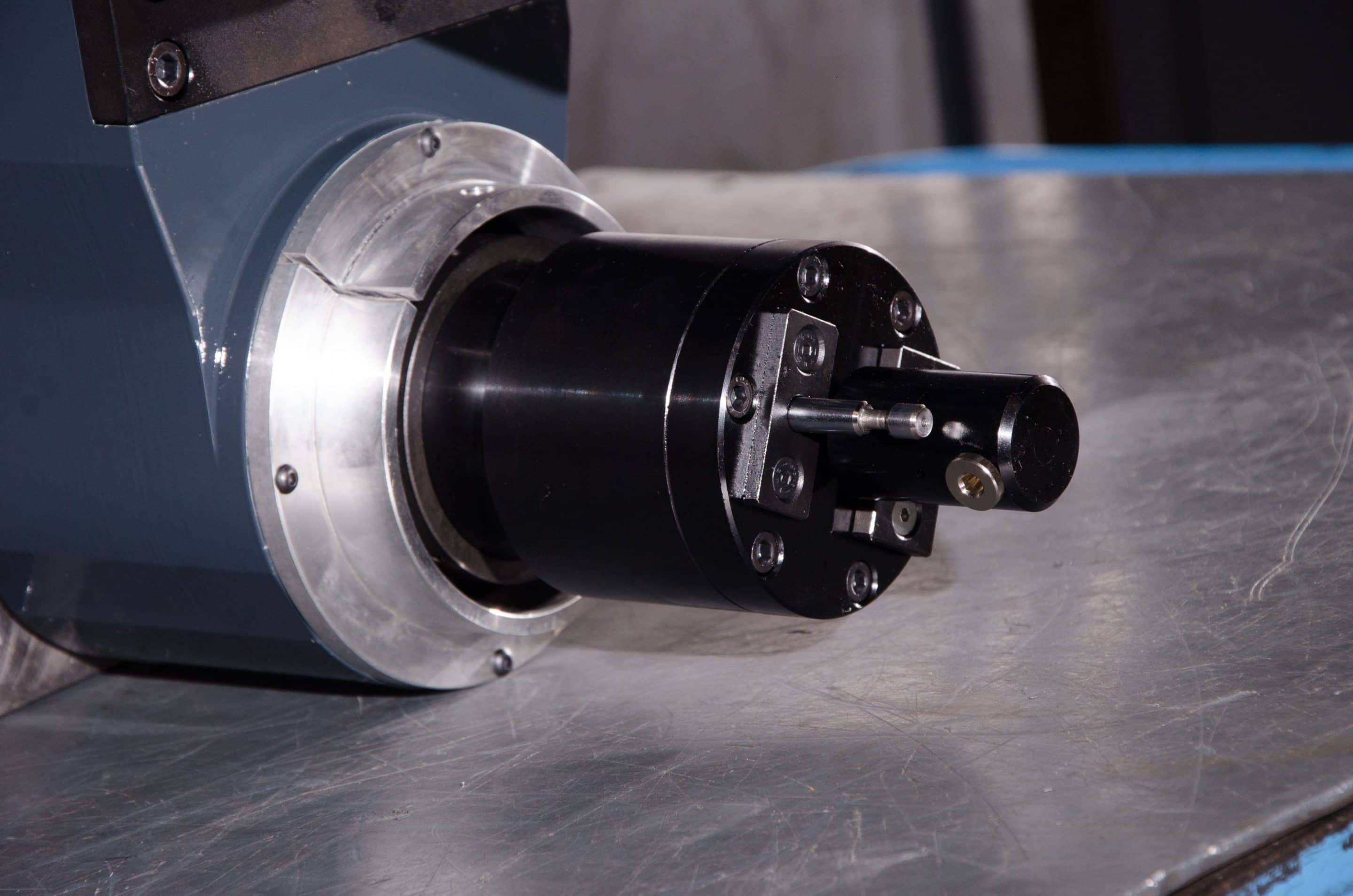

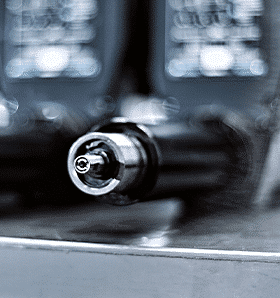

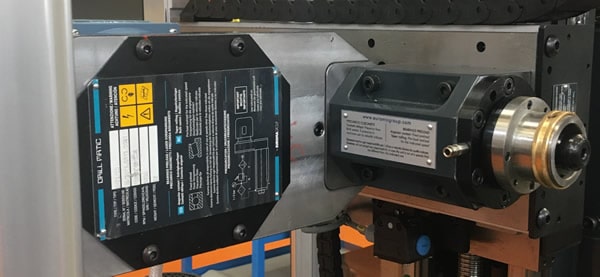

Today, the implementation of the product, strongly requested by the Market, makes it possible to set up even the smallest motorized spindle size with HSK shafts, which give the operator the possibility to perform a tool change and a presetting outside the machine with extreme precision and speed.

Taking advantage of both the taper and the stop of the tool holder on the face of the female cone, the HSK connection guarantees great rigidity during machining, both for drilling and threading but also and above all for milling that involves important radial efforts.

The rigidity then translates into the possibility of having high rotation speeds at extremely reduced concentricity, better performances and ever lower cycle times.

Besides, thanks to the extreme ease for the operator to perform the manual unclamping of the shank, the HSK system is strongly recommended for all those applications where the maintenance operations and the accesses inside the machinery are limited due to the reduced space or where the spindle is mounted in vertical position.

In fact, compared with the version with pull stud for ISO shank, where the use of two wrenches is necessary, the operator doesn’t need to support the shank to prevent it from falling, since it’s sufficient to use an Allen key and thereby to have the possibility of holding the shank with hands.

Like for the ISO version, the passage of the coolant through the spindle with adduction from the rear rotary joint is available. Moreover, our staff is always available to help with any type of request.

News

Same concept, new design,

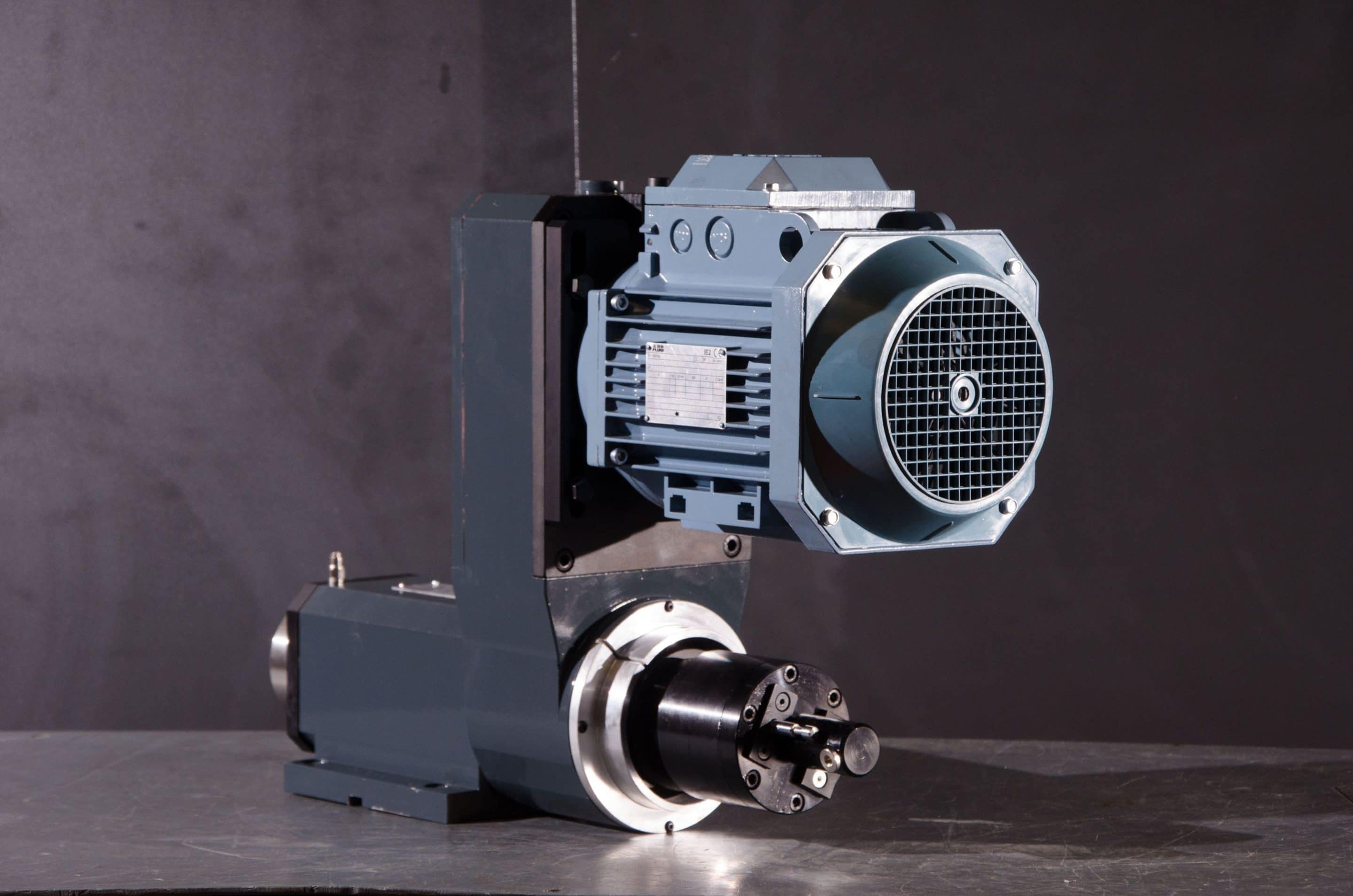

EUROMA motorized spindles equipped with an automatic tool change system have a new look and are dedicated mostly to the gantry machine sector.

To be precise, we are talking about sheet metal working machines, which is plasma cutting, laser cutting and oxy-fuel cutting.

Besides sheet metal laser cutting, obtained with the above mentioned, performing mechanical precision operations – such as drilling and threading – within the process is now an usual thing. Nowadays, it would be unthinkable to bring the chip removalprocess out of the machine and move the piece in several stages. For most of the world’s largest gantry machine manufacturers, the old concept of the revolver head, currently limited in its power and torque transmitted capabilities, is being abandoned to leave more and more space for the use of the motorized spindles, CNC feed with automatic tool change system and tool rack. This concept is very similar to that of machining centers.

In fact, EUROMA motorized spindles offer great strength, reliability and precision. Furthermore, the new design, developed especially for the needs of this type of machine, further enhances its features.

What has most significantly improved is the dimensional development of the pneumatic tool change system which is extremely compact if compared with the previous one, with a diameter of only 150 mm. The single-acting cylinder generates an unlocking thrust to the plate springs of 14000N in the ISO40 version, while for mechanical retention the pulling force reaches 18000N thanks to the thrust multiplier.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

There’s also a fourth sensor mounted on the rear part of the cylinder, which reads the actual return, thus ensuring the mechanical pull of the springs. The fifth sensor is mounted directly on the shaft and reads its rotation to

manage the timing of the two ISO dowels.

The extended spindle shaft makes it possible to reduce the working strokes to a minimum, thus avoiding any space problem usually due to the transmission casings and the motors that are applied. Nowadays, the range has 3 spindle sizes (DX28 – DX38 – DX58) with the possibility to choose between ISO40 and ISO50 shank.

The spindles with this new system are perfectly suitable with the EX model feed slides, which can be used to perform the working strokes with ball screw and CNC motor. If you need more information, please do not hesitate to contact us!

Exhibitions

Euroma Group is ready for the participation in Metalloobrabotka, the International Exhibition of Equipment, Instruments and Tools for the Metalworking Industry that will open the doors of the Expocenter Fairgrounds in Moscow from the 27th to 31st May.

“Each event is an opportunity to grow and develop our business network, to create collaborations, projects and jobs – declared the president of Euroma Group Valerio Veronesi – Each exhibition is an opportunity: in this way is also the Moscow showcase , which this year celebrates its twentieth edition and is growing more and more. With the UK both and the participation of exhibitors from Australia last year, Metalloobrabotka becomes more and more global: Euroma Group does not want to miss this appointment“.

The last edition of Metalloobrabotka ended with over 32.400 visitors, 1100 exhibitors and more than 41.000 square meters of exhibition space. Initially the event took place once every five years, then once every two years and finally from 2010 it has become annually, reaching over 35 years of history for a total of 20 editions.

Visit us at Pavilion 8 Hall 3 Stand C10

News

Reach every corner of the world with our products is the challenge we have set ourselves

In the era of Industry 4.0 we can afford ideas and concepts that until just few years ago were almost prohibitive and which are now commonplace. But technology alone cannot do anything, if you do not even have a professional and technical presence on the market.

EuromaGroup has a widespread presence throughout the global territory through its dealers, but is proud to dispose of and make available to its customers an highly experienced technical sales representative.. And with this occasion we are pleased to introduce you Beatrice Avanzini.

Beatrice Avanzini is our worldwide interface for all three macro categories of Euroma Group products.

Specifically, Beatrice Avanzini is your direct contact for:

Drillmatic in Russia, China and the United States

CMT all over the world

ISA all over the world

If the mountain won’t come to Mohammed….

For any request or technical/commercial information please contact us!

News

It is with extreme pride that we present the initiative to sensitize our staff to the phenomenon of smoking.

For the first time in a company in Bologna, Mr. Dr. Vincenzo Zagà, pulmonologist and president of the Italian Society of Tobaccology, has held a valuable intervention on the properties of tobacco and the serious economic, psychological, social and physical implications that it determines both on smokers and non-smokers.

Conscious and healthy!

http://www.tabaccologia.it

Tobacco meeting with Dr. Zagà – 05/12/2018

Area job Euromagroup

Exhibitions

Euroma Group confirms its presence at the eighteenth edition of MECSPE, the reference fair for the manufacturing industry, which will take place in Parma from 28 to 30 March 2019.

“MECSPE is an important window not only to present our new products – affirmed Valerio Veronesi, President of Euroma Group – but also to examine the affinity and differences between the most innovative solutions that affect many sectors of the industry”.

With 110.000 square meters of exhibition space, an attendance of over 53.000 visitors and a showcase of around 2.260 companies divided into 12 thematic halls, MECSPE offers a complete overview of the production and the industrial supply chain.

Euroma Group will be present at Hall 4.1, Stand A32.

Exhibitions

From January 30th to February 1st Euroma Group will be exhibitor of the I + E Industriemesse Schwarzwald in Friburg, Hall 3, Stand N103.

The fair takes place every two years and is the largest in South-Western Germany regarding not only electronics and electrical engineering, but also metalworking and automotive.

“At the Industriemesse in Friburg – declared the President of Euroma Group, Valerio Veronesi – hundreds of exhibitors meet to discuss important topics such as the technological perspectives of the sector, the access to the global market and the new business models. There are high-level conferences and for Euroma Group it is an opportunity to present our products, to speed up the future “.

The main sectors of the event are Electrical Engineering, Automation, Metalworking, Mechanical Engineering, Plastics Technology and Industrial Services, presented in three halls with an exhibition area of 6.000 square meters.

News

Opened the new Opportunities entirely dedicated to the spontaneous applications and open positions in Euroma Group.

Not just a form through which users can submit their professional profile to the Human Resources Department, but also a space to highlight the Group’s attention to new generations and young professionals.

“We want to offer real opportunities to young people – commented Valerio Veronesi, President of EuromaGroup – whether they are specialized workers, salesman or designers. We understand the need of our young, to finally compete in a working environment, to test themselves and demonstrate their actual skills. Once the chosen course of study has been completed young people must feel welcomed by the market and, why not, also desired in Euroma Group we value the energies and enthusiasm of those who want to identify their own professional path and find a working identity, paying great attention to the younger ones, because they are healthy carriers of passion and innovation

Not having previous experience is not a fault – specified Veronesi Everyone of us started without experience, then over time we acquire knowledge and skills. But if we do not give space to those who want to build an experience now, there would be no generational change and the push for innovation would probably be extinguished. Young people represent a bridge towards the future: they are the ones who lead us towards the scenarios that await us, and the treatment we reserve for them will be reflected in the goodness of the results we are going to achieve.. That’s why we carefully evaluate all the profiles of the young candidates they are our team of tomorrow We therefore invite those who are already working in Euroma Group or who follow the Group’s activities – the President specified – to highlight our sensitivity towards the new generations of workers: we are looking for motivated and deserving people “

The Opportunities section shows the contributions put into place by the company to improve the quality of life from work: from vocational training courses, such as those of foreign languages with teachers to the initiatives aimed at promoting a healthy lifestyle, such as nutritional advice available to employees for an optimal approach to the table. Even the Public Speaking courses they are promoted in order to create moments of aggregation and to help the resources in the improvement of their expressiveness in public.

“We want you to know -concluded Veronesi- C We invest on our resources also from the human point of view: that their well-being is of interest to the company and that the goal is to work in a positive and healthy environment.

FIND OUT MORE >>

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.