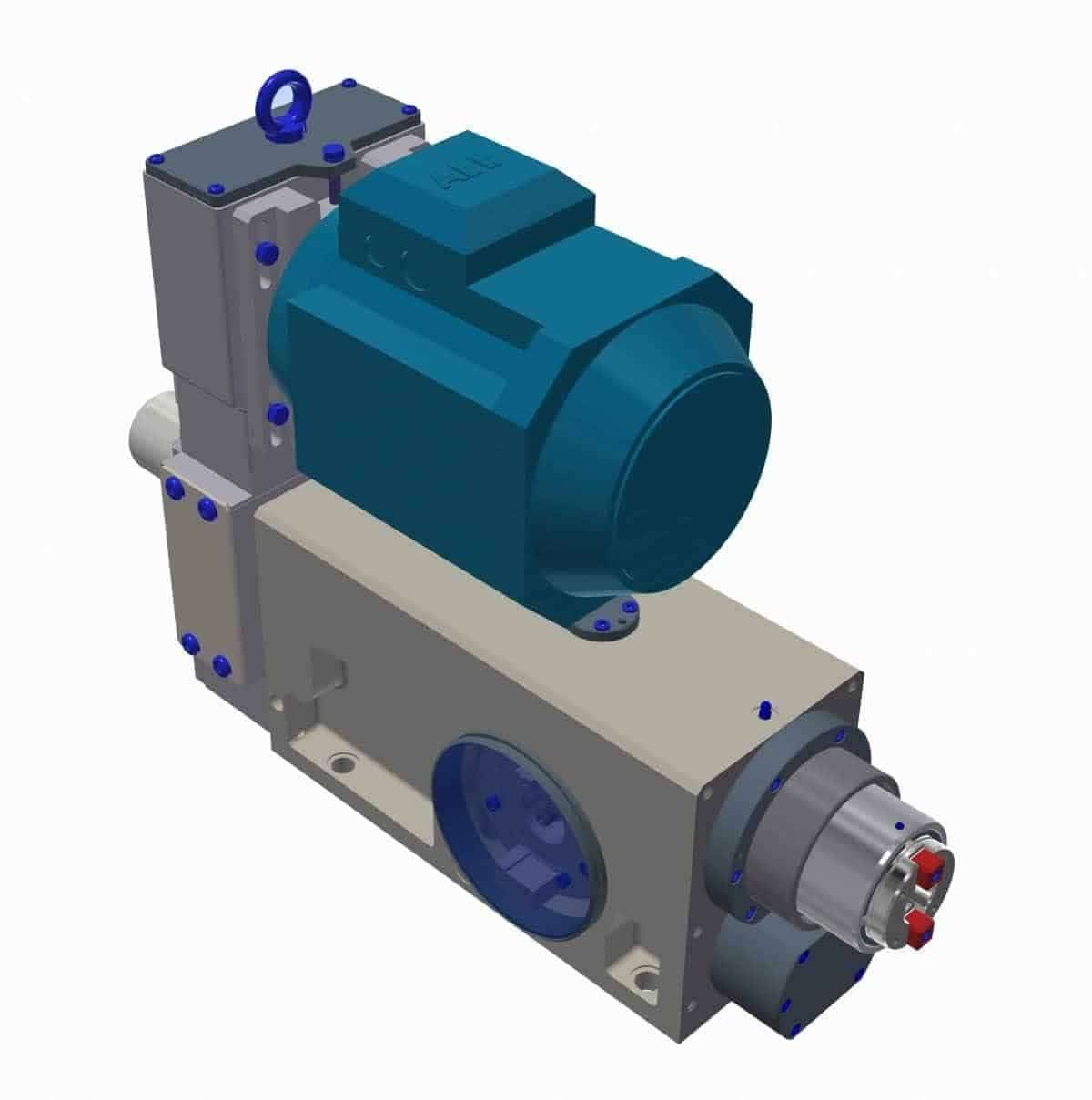

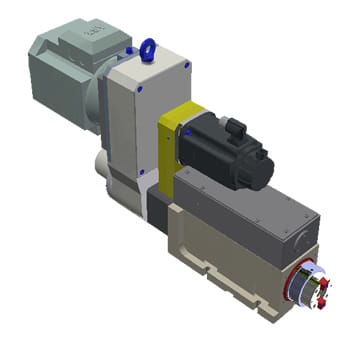

Electro-pneumatic / CNC quill drilling units

Electro-pneumatic drilling units by Drillmatic can perform any axial machining such as drilling, countersinking, reaming, counterboring, etc ...

Each unit has a rapid approach stroke

and an operating stroke adjusted by a hydraulic shock absorber. Mechanical adjustments of stroke and feed speed are quick and accessible.

The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

| Image | SKU | Name | Drilling capacity on steel R=60 ø mm | Stroke [mm] | Motor 2P [Kw] | Motor 4P [Kw] | Motor 6P [Kw] | Min.speed [rpm] | Max. speed [rpm] |

|---|

| DXP10.75 | Electro-pneumatic drilling units | 10 | 75 | 0,75 | 0,55 | 0,55 | 400 | 8400 |

| DXP10.150 | Electro-pneumatic drilling units | 10 | 150 | 0,75 | 0,55 | 0,55 | 400 | 8400 |

| DXP18.100 | Electro-pneumatic drilling units | 18 | 100 | 1,5 | 1,5 | 1,1 | 160 | 4500 |

| DXP18.150 | Electro-pneumatic drilling units | 18 | 150 | 1,5 | 1,5 | 1,1 | 160 | 4500 |

| DXP24.120 | Electro-pneumatic drilling units | 24 | 120 | 3 | 2,2 | 2,2 | 300 | 4000 |

FEATURES

- Pneumatic feed at 6bar

- Mechanical adjustment of rapid approach stroke and operating stroke

- Coaxial hydraulic shock absorber to adjust feed speed

- 3 Mechanical sensors for stroke adjustment

- Spindle supported by a set of taper roller bearings

- Three-phase motor usable inverter

- Concentricity 0,02mm

ACCESSORIES

- Peck-feed function

- Speed reducer

- Multi spindle heads

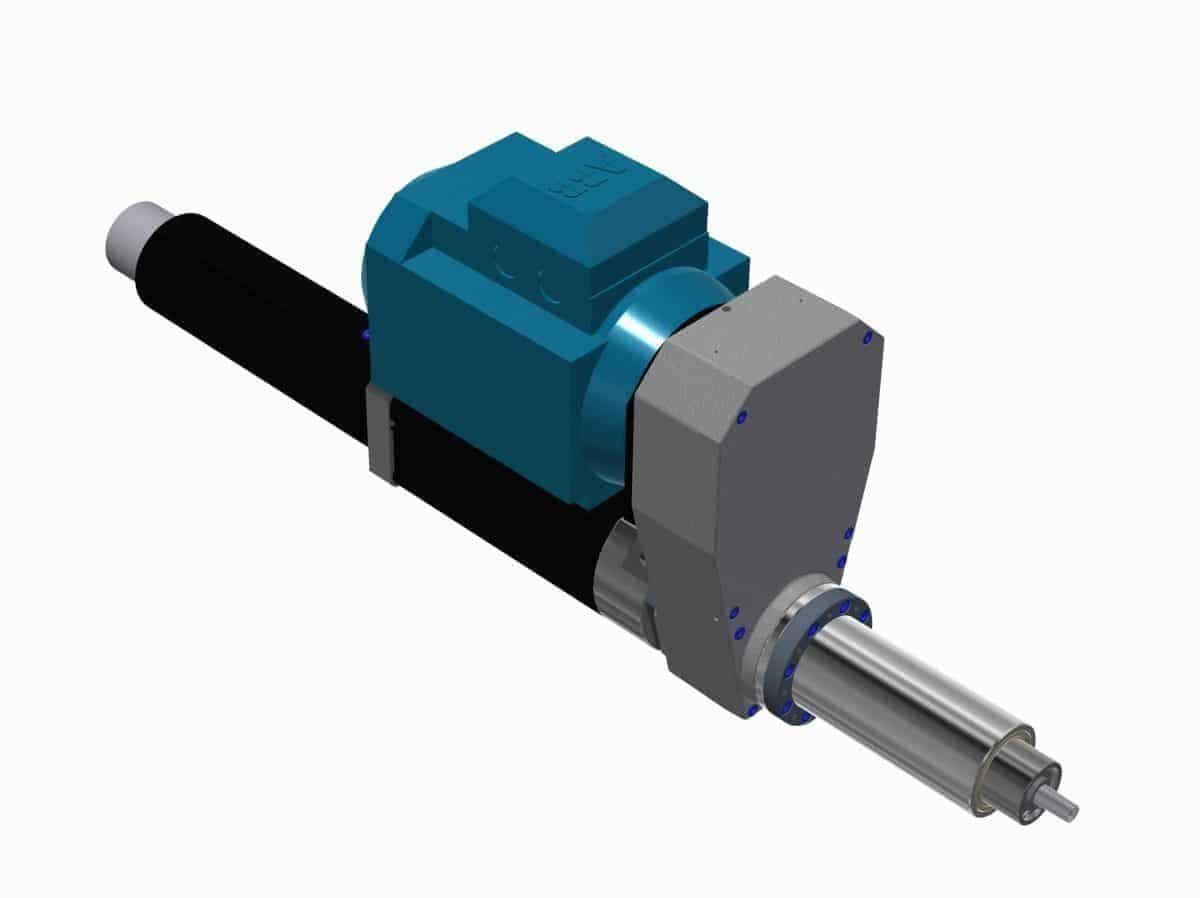

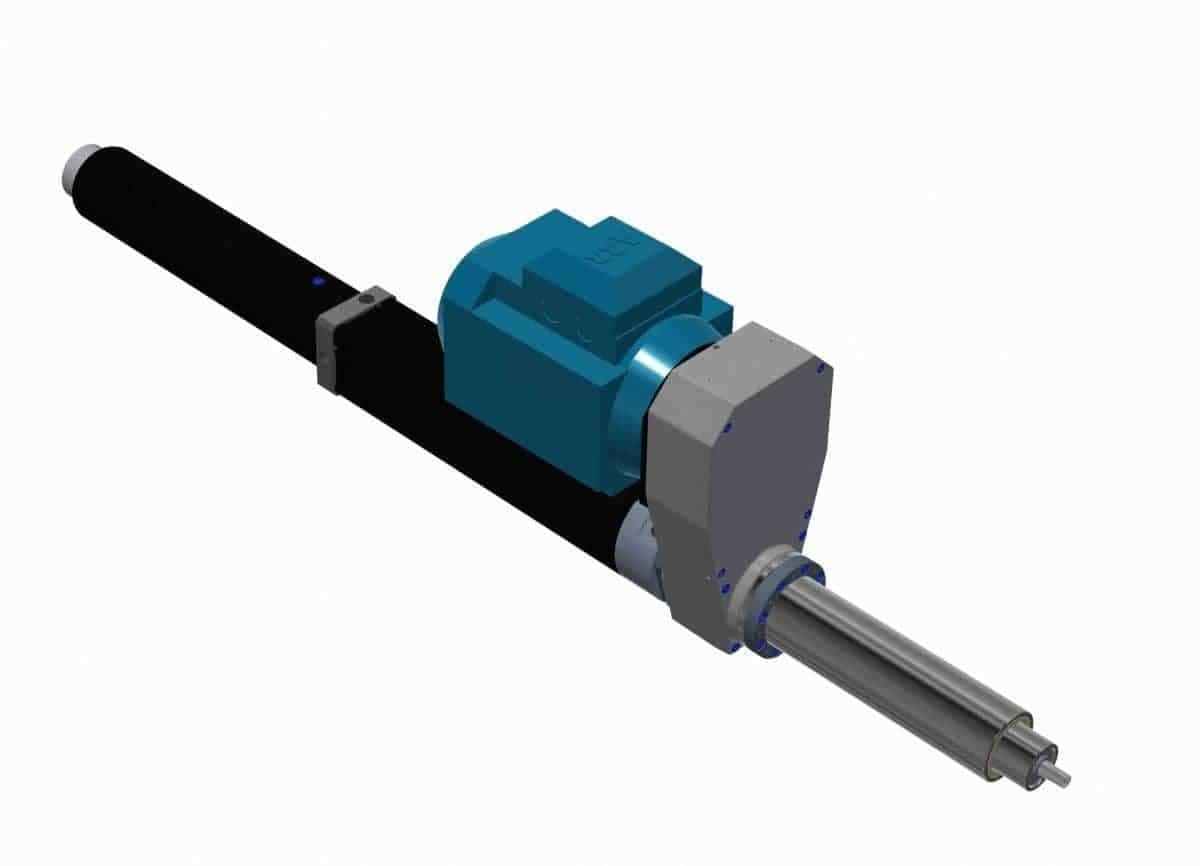

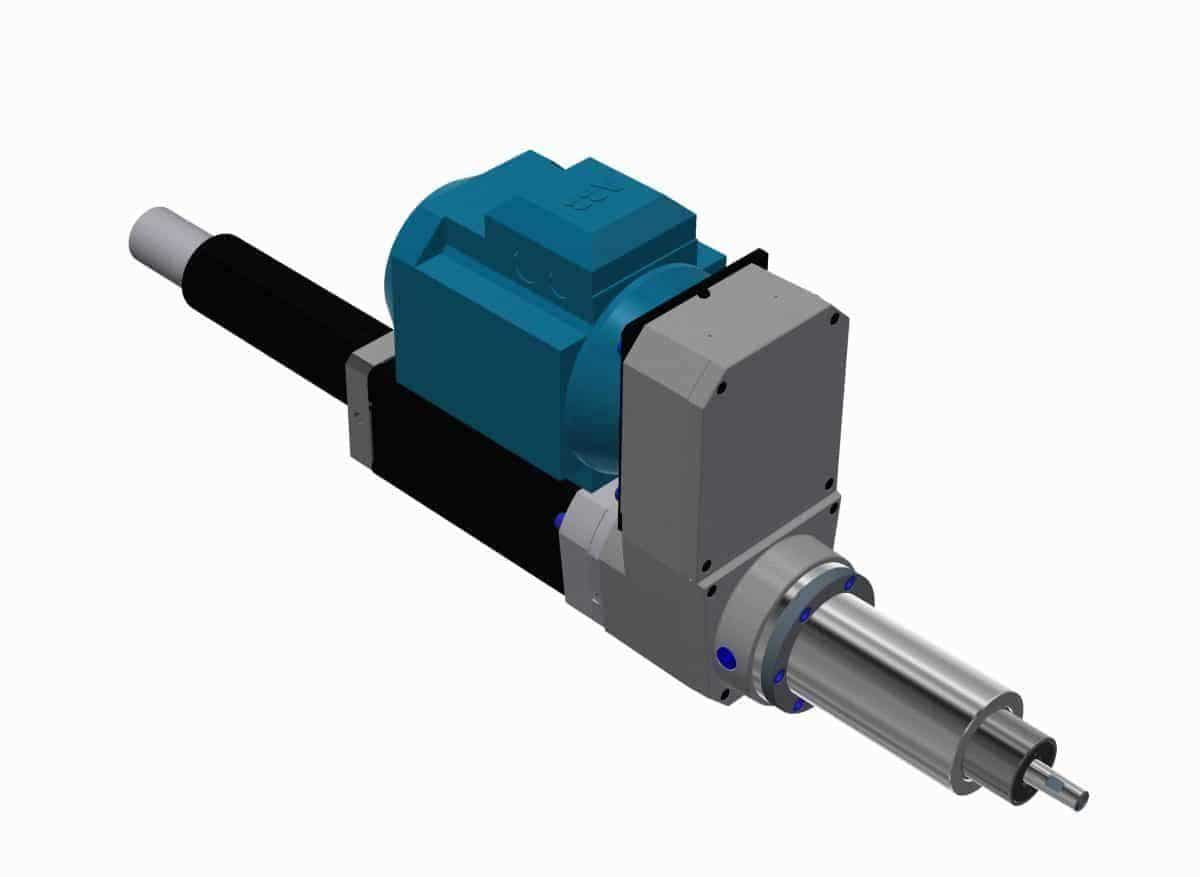

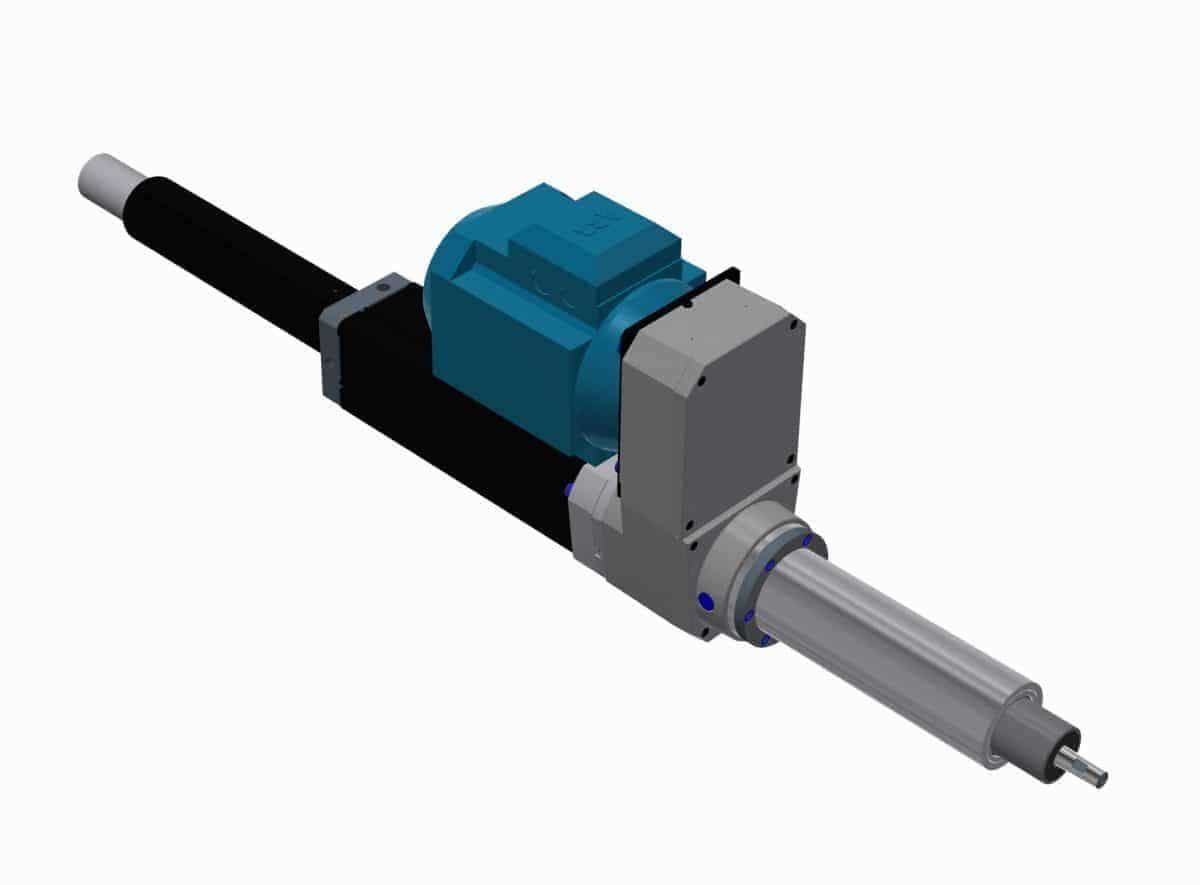

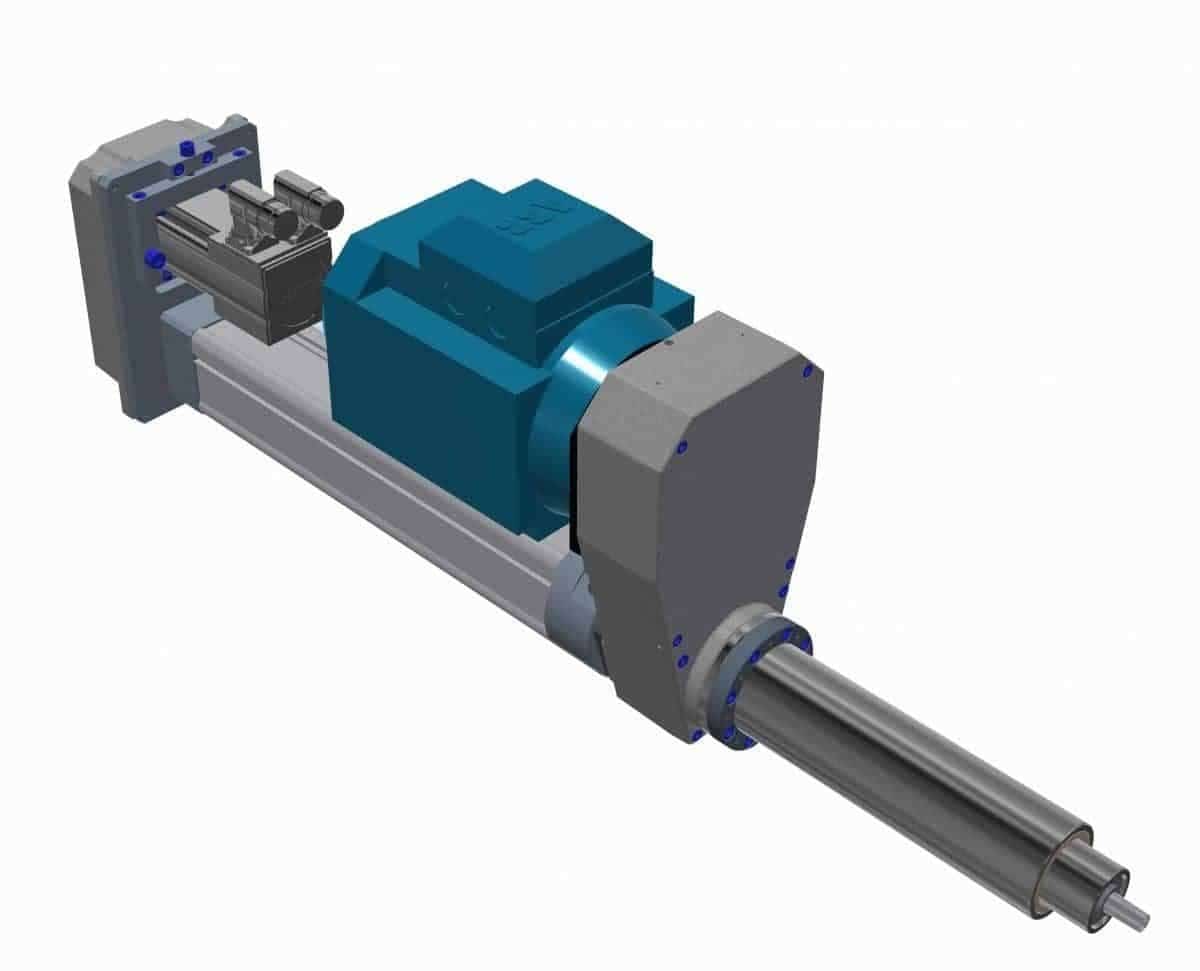

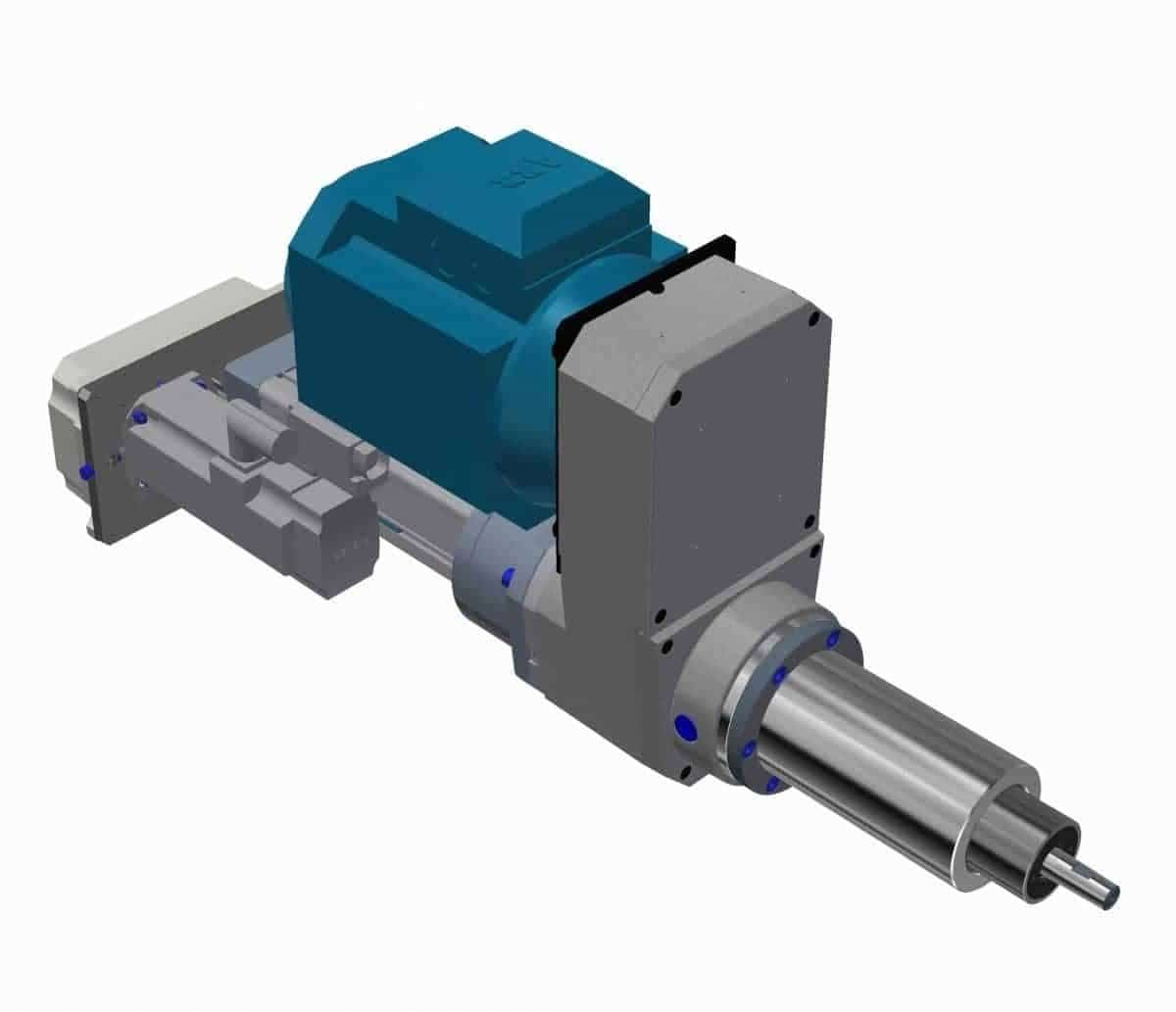

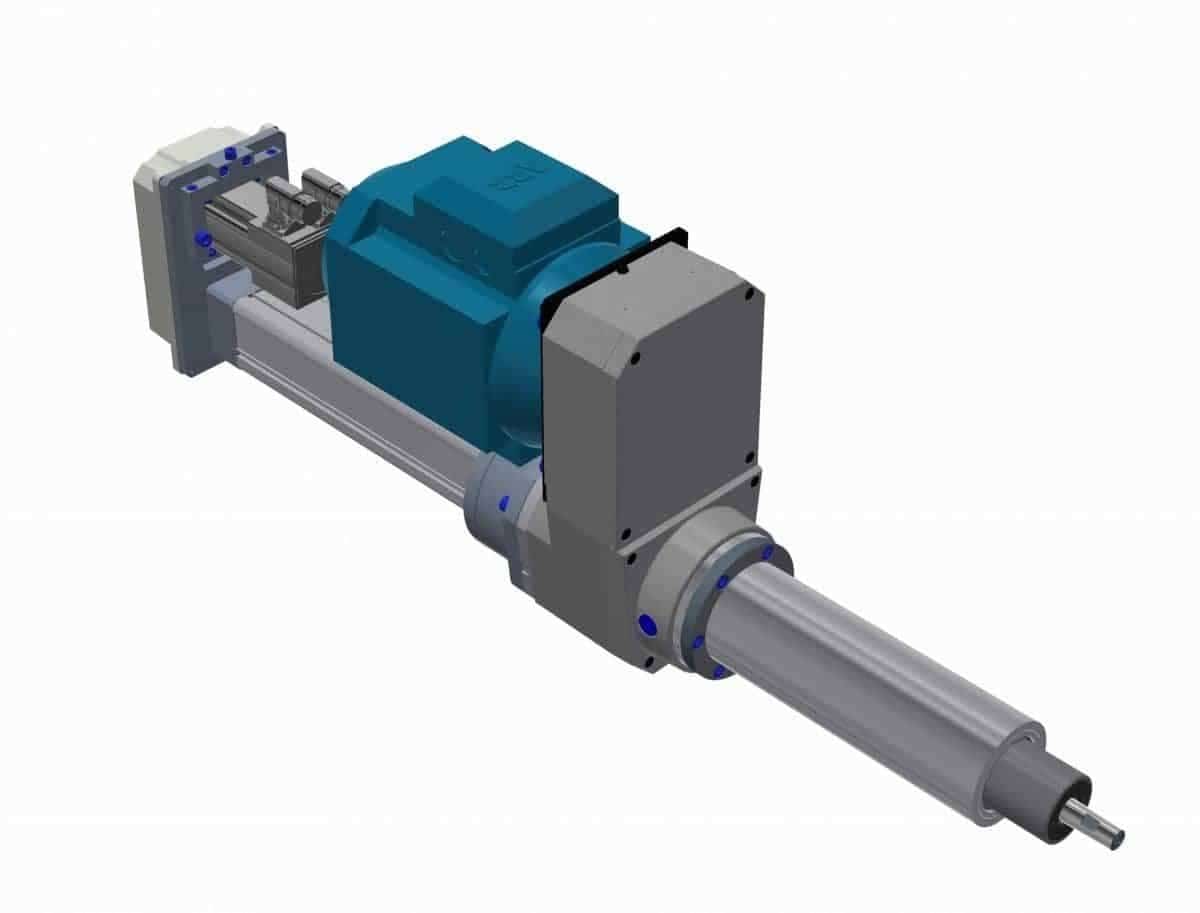

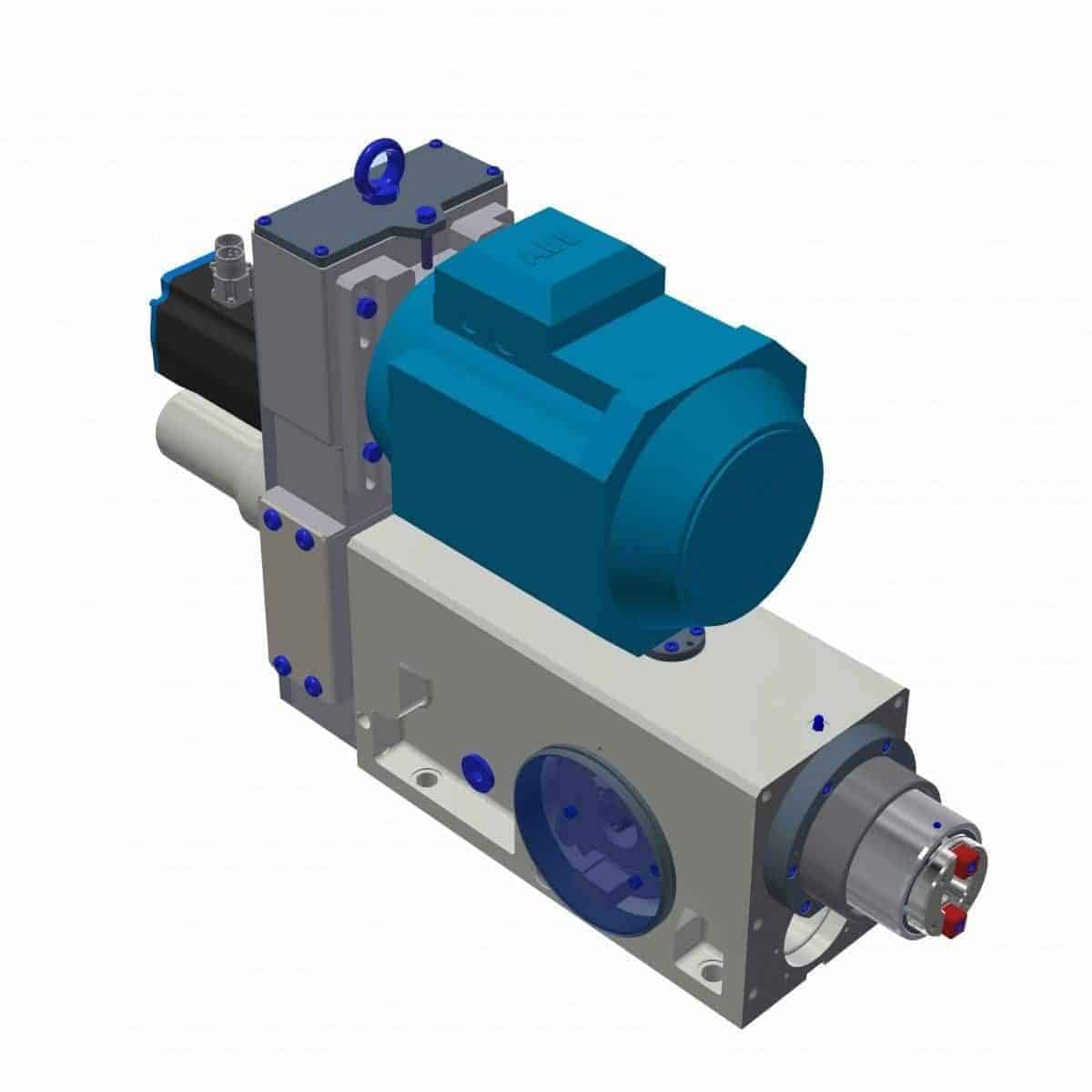

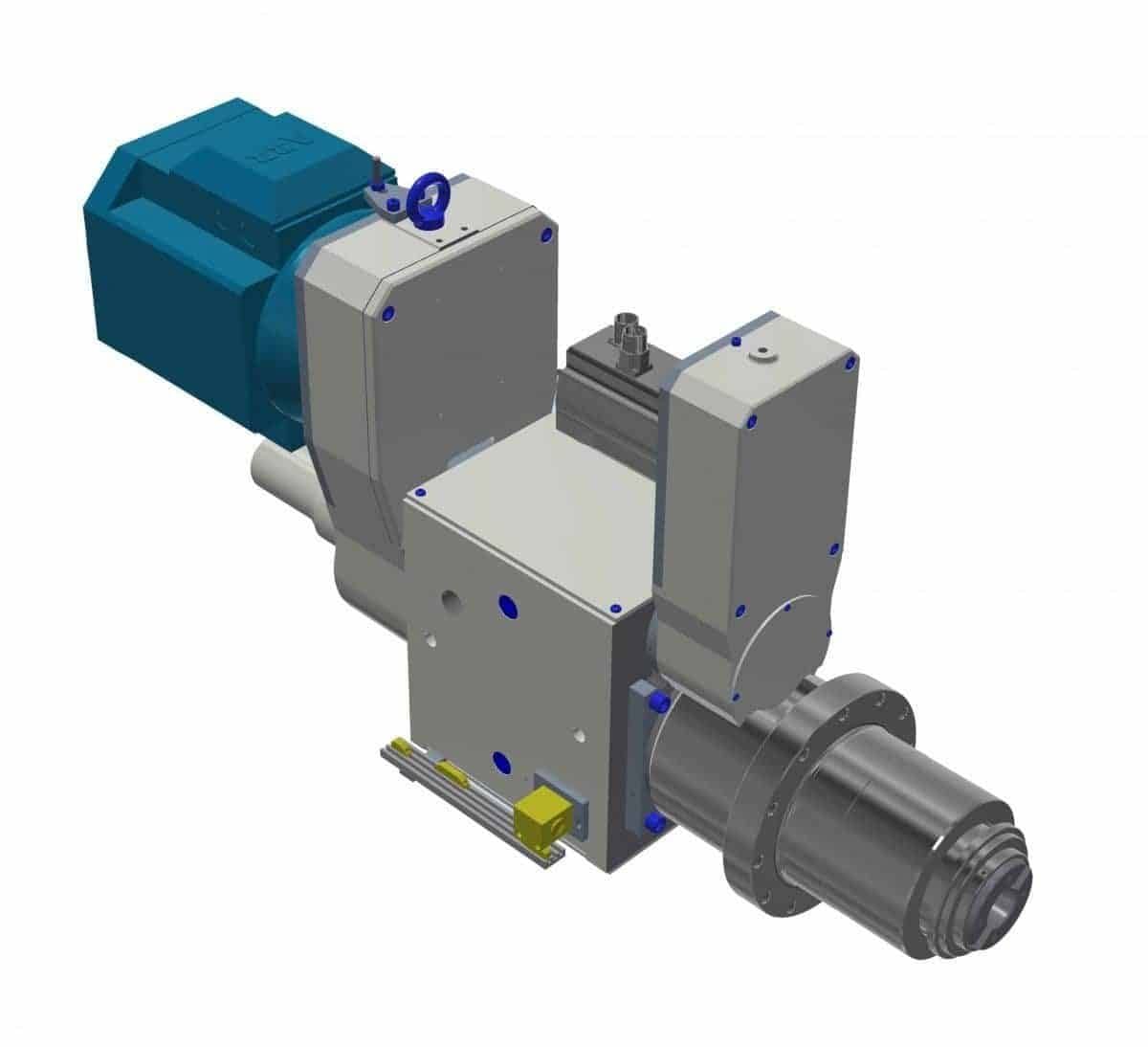

CNC quill units

CNC Machining Units by Drillmatic can perform any type of axial machining, such as drilling, threading, reaming, counterboring, etc ...

The feed axis can be moved by means of a ball screw and CNC motor allows an effective and precise management of the stroke.

The basic version involves the use of a three-phase motor for spindle rotation. However, it is possible to set up the unit with two brushless motors to perform CNC interpolation.

The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

| Image | SKU | Name | Stroke [mm] | Motor 2P [Kw] | Motor 4P [Kw] | Motor 6P [Kw] | Drilling capacity on steel R=60 ø mm | Min.speed [rpm] | Max. speed [rpm] |

|---|

| DXE10.60 | CNC Machining units | 60 | 0,75 | 0,55 | 0,55 | 10, M12 | 400 | 8400 |

| DXE10.130 | CNC Machining units | 130 | 0,75 | 0,55 | 0,55 | 10, M12 | 400 | 8400 |

| DXE16.90 | CNC Machining units | 90 | 1,5 | 1,5 | 1,1 | 16, M20 | 160 | 4500 |

| DXE16.130 | CNC Machining units | 130 | 1,5 | 1,5 | 1,1 | 16, M20 | 160 | 4500 |

| DXE23.115 | CNC Machining units | 115 | 1,5 | 1,5 | 1,1 | 25, M30 | 300 | 4000 |

| DXE24.120 | CNC Machining units | 120 | 3 | 2,2 | 2,2 | 26, M30 | 300 | 4000 |

| DXE42.160 | CNC Machining units | 160 | 3 | 2,2 | 2,2 | 38, M40 | 160 | 4000 |

FEATURES

- Feed by means of ball screw

- 3 Mechanical sensors for stroke adjustment

- Spindle supported by a set of taper roller bearings

- Three-phase motor usable inverter

- Concentricity 0,02mm

ACCESSORIES

- Speed reducer

- Provision for 2 CNC motors

- Multi spindle heads