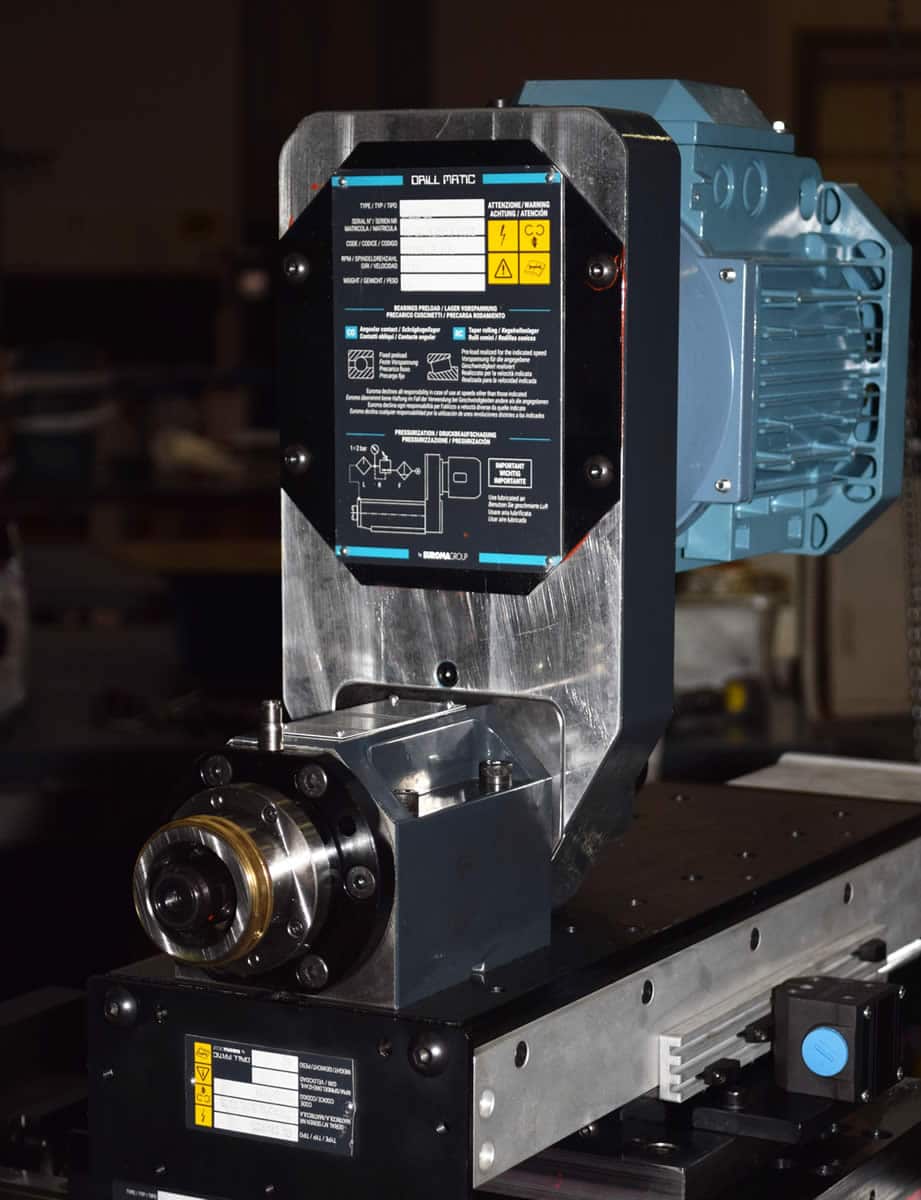

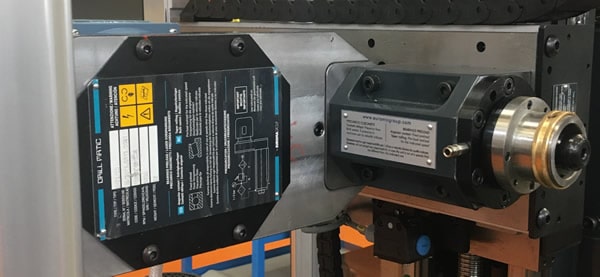

Today, the implementation of the product, strongly requested by the Market, makes it possible to set up even the smallest motorized spindle size with HSK shafts, which give the operator the possibility to perform a tool change and a presetting outside the machine with extreme precision and speed.

Taking advantage of both the taper and the stop of the tool holder on the face of the female cone, the HSK connection guarantees great rigidity during machining, both for drilling and threading but also and above all for milling that involves important radial efforts.

The rigidity then translates into the possibility of having high rotation speeds at extremely reduced concentricity, better performances and ever lower cycle times.

Besides, thanks to the extreme ease for the operator to perform the manual unclamping of the shank, the HSK system is strongly recommended for all those applications where the maintenance operations and the accesses inside the machinery are limited due to the reduced space or where the spindle is mounted in vertical position.

In fact, compared with the version with pull stud for ISO shank, where the use of two wrenches is necessary, the operator doesn’t need to support the shank to prevent it from falling, since it’s sufficient to use an Allen key and thereby to have the possibility of holding the shank with hands.

Like for the ISO version, the passage of the coolant through the spindle with adduction from the rear rotary joint is available. Moreover, our staff is always available to help with any type of request.