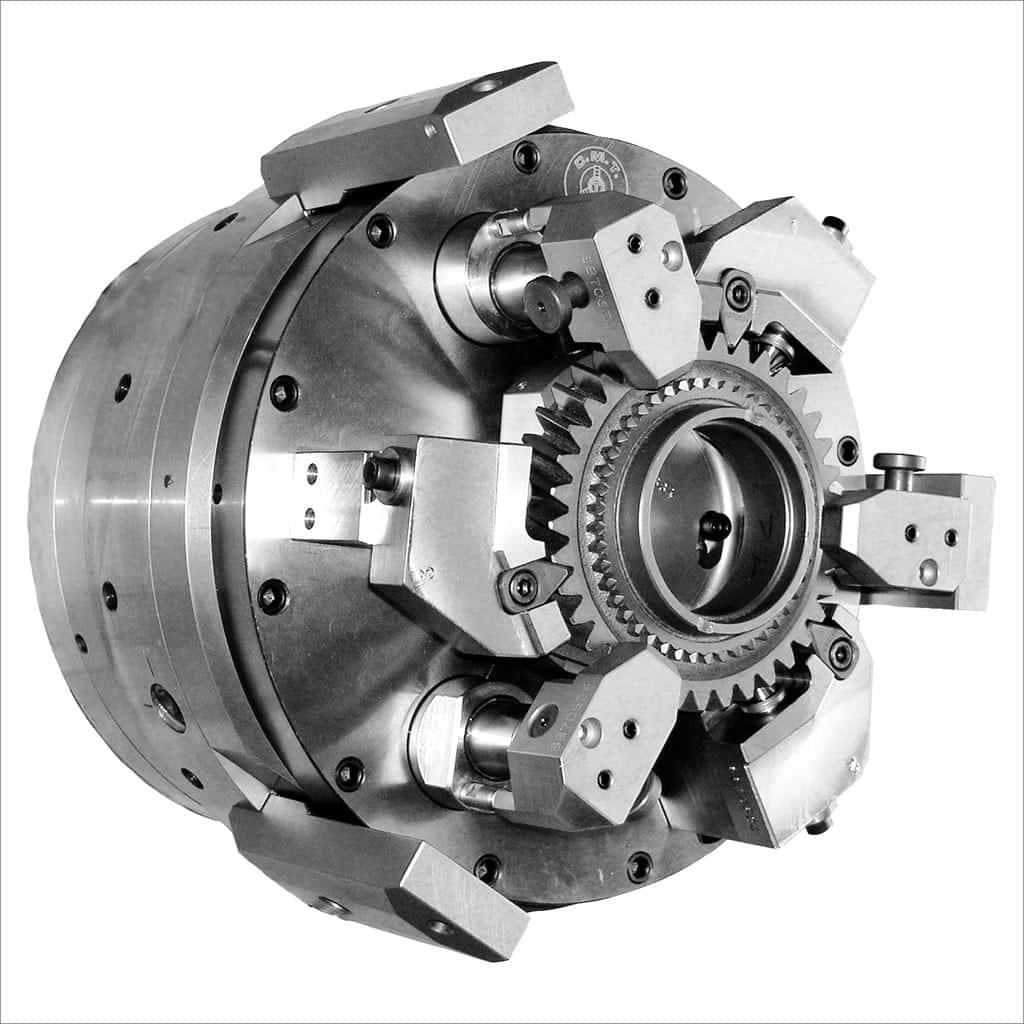

CMT

Automatic quick change carrier with locators and recovering rotating arms

• High rigidity during machining

• Repeatability accuracy within 0.01 mm

• Quick change without any further adjustment

• High centering accuracy on primitive gear diameter

• High roundness accuracy in hole execution • High rotation speed

• High cutting on hard turning • Suitable to machine outer taper by means of recovering arms

• Manual or automatic loading

• Gear presence check (PEL)

• Balanced system

• Suitable to work with external dressing wheel holders (for grinding)

Radial and front clamping

The gear is loaded manually or automatically presetted through the prelocators than clamped by the locators. After the arms close down with rotating and axial movement clamping in very rigid way the gear to allow hard machining. Mechanism driving the arms is swivelling to have a correct stirrup effect. Carrier mechanism and stirrup one are driven separately therefore needing a double clylinder. The machine is able to machine with such a sequence the gear hole. When machining the taper gear the carrier is still clamping the workpiece.

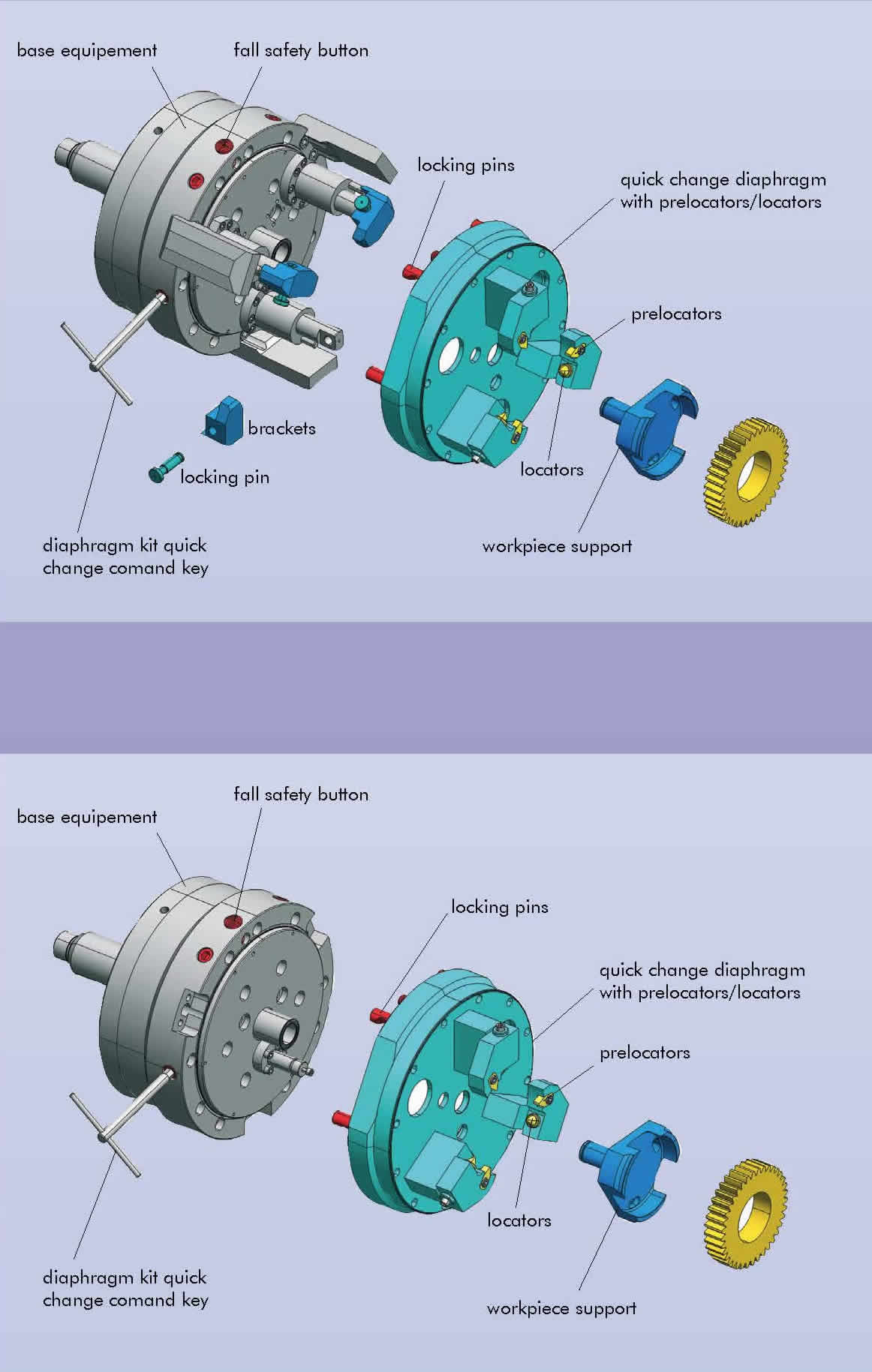

Radial clamping

Radial clamping

The gear is loaded on the carrier, presetted through the prelocators than clamped by means of locators. The mechanism is driven by one only rotary cylinder. With such a sequence the machine can machine the gear hole and taper.