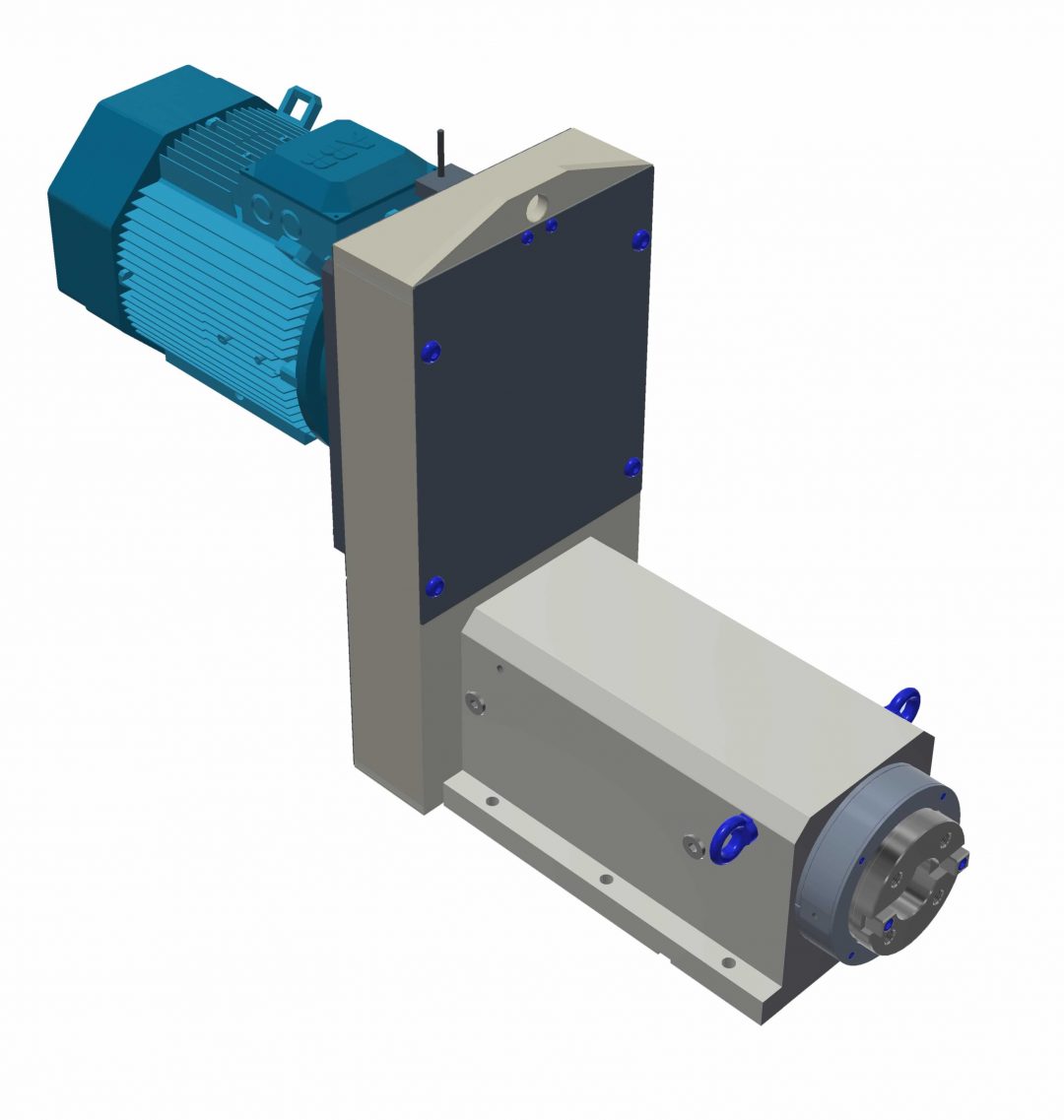

Machining spindles

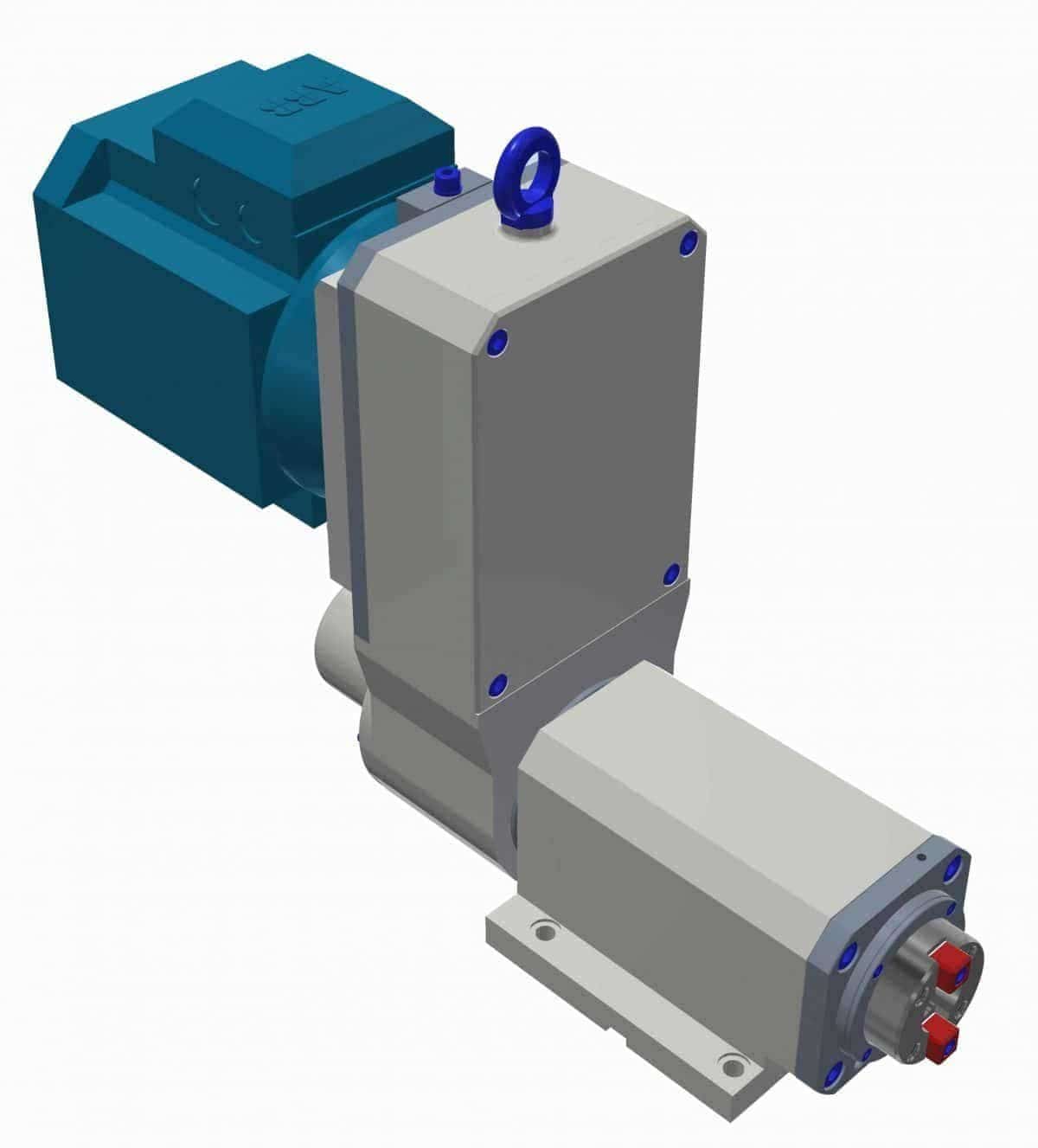

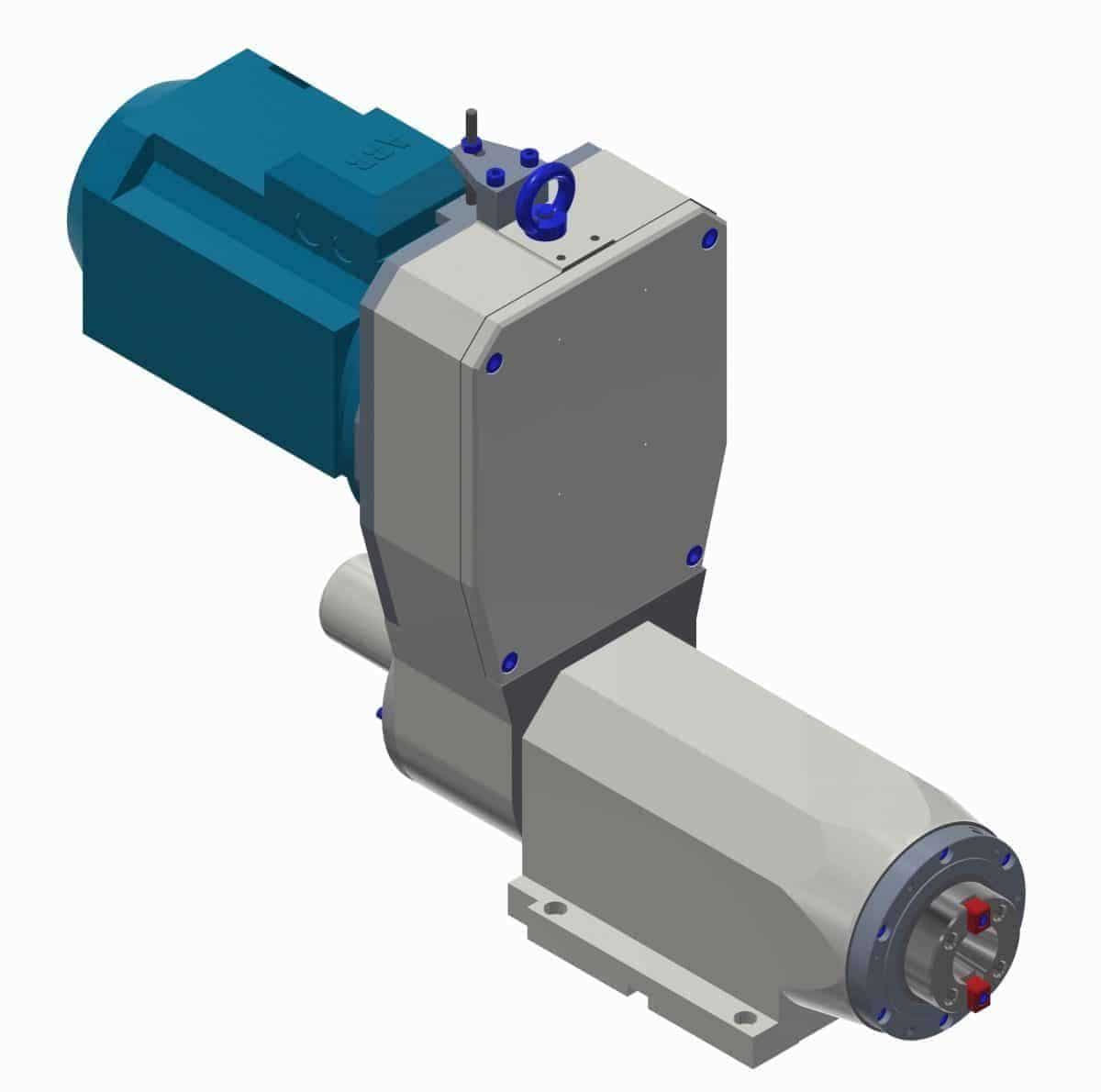

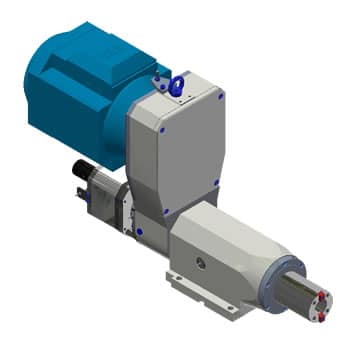

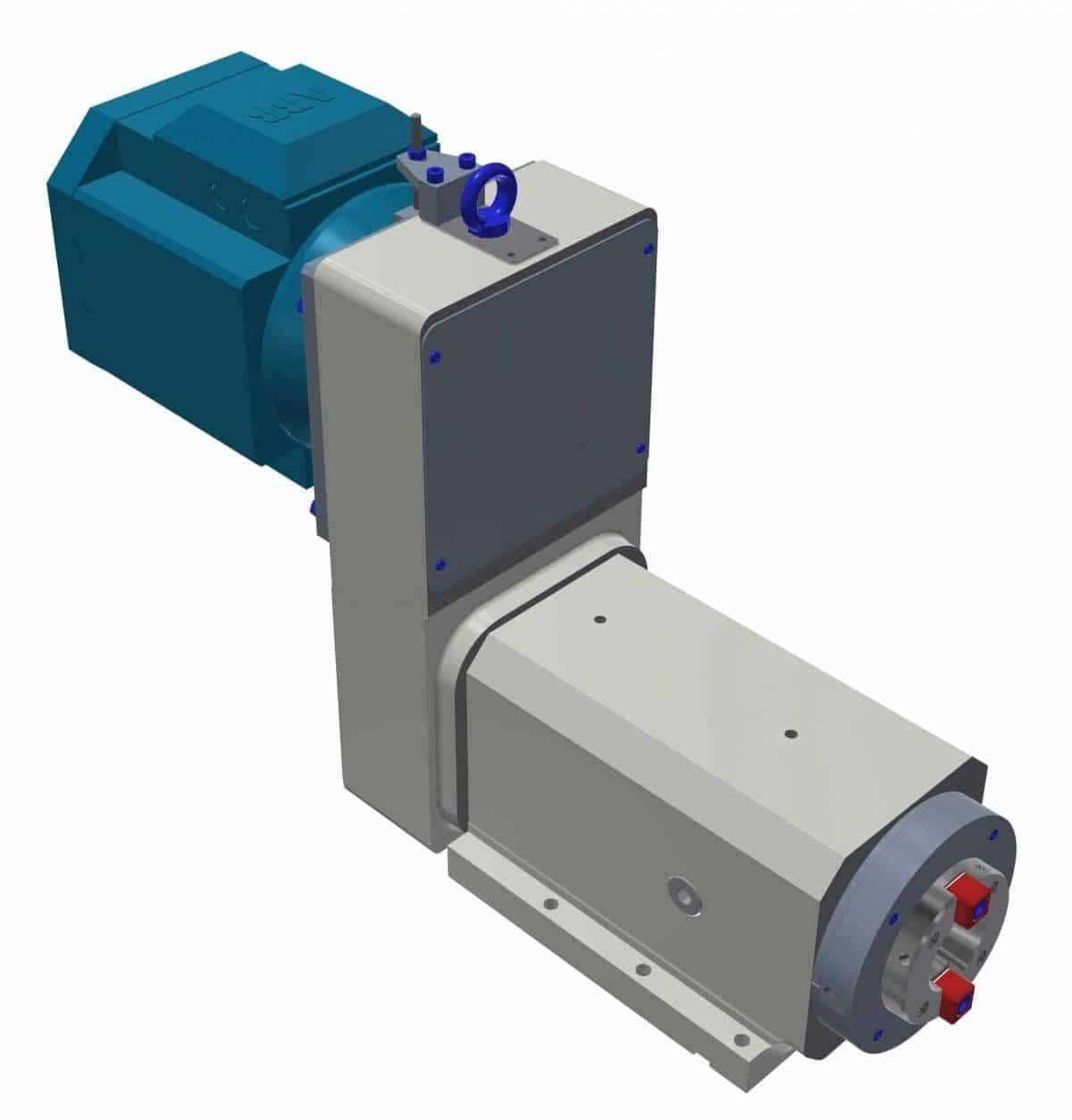

Machining spindles by Drillmatic are suitable for both axial drilling and threading, as well as heavier radial machining such as milling, boring and cutting. The feed stroke is managed by the EX series CNC slide units.

All spindles are configurable with ISO or HSK connections, in manual or automatic version.

Depending on the machining to be performed and the speed of rotation, it is possible to provide the spindles with taper roller bearings or with angular contact.

The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

| Image | SKU | Name | Drilling capacity on steel R=60 ø mm | Min.speed [rpm] | Max. speed [rpm] | Motor 2P [Kw] | Motor 4P [Kw] | Motor 6P [Kw] |

|---|

| DX22 | Machining spindles | 18 | 600 | 8400 | 1,5 | 1,5 | 1,1 |

| DX28 ISO 30 | Machining spindles | 35 | 400 | 8400 | 1,5 | 1,5 | 1,1 |

| DX28 ISO 40 | Machining spindles | 35 | 400 | 8400 | 3 | 2,2 | 2,5 |

| DX38 ISO 40 | Machining spindles | 40 | 160 | 3600 | 3 | 2,2 | 2,2 |

| DX38 ISO 50 | Machining spindles | 50 | 160 | 3600 | 5,5 | 5,5 | 4 |

| DX38L | Machining spindles | 50 | 160 | 3600 | 3 | 2,2 | 2,2 |

| DX58 | Machining spindles | 50 | 160 | 3600 | 7,5 | 7,5 | 5,5 |

| DX88 | Machining spindles | 60 | 160 | 3600 | 7,5 | 7,5 | 5,5 |

FEATURES

- ISO / HSK Spindle connection

- 90 ° / 60 ° rotating transmission cover

- Motor in front or rear position

- Spindle supported by a set of taper roller bearings / angular contact bearings

- Three-phase motor usable inverter

- Concentricity 0.01mm

ACCESSORIES

- Balanced shaft for high speeds

- Coolant through facility

- Automatic pneumatic / hydraulic tool change

- CNC spindle motor

- Multi spindle heads