CMT

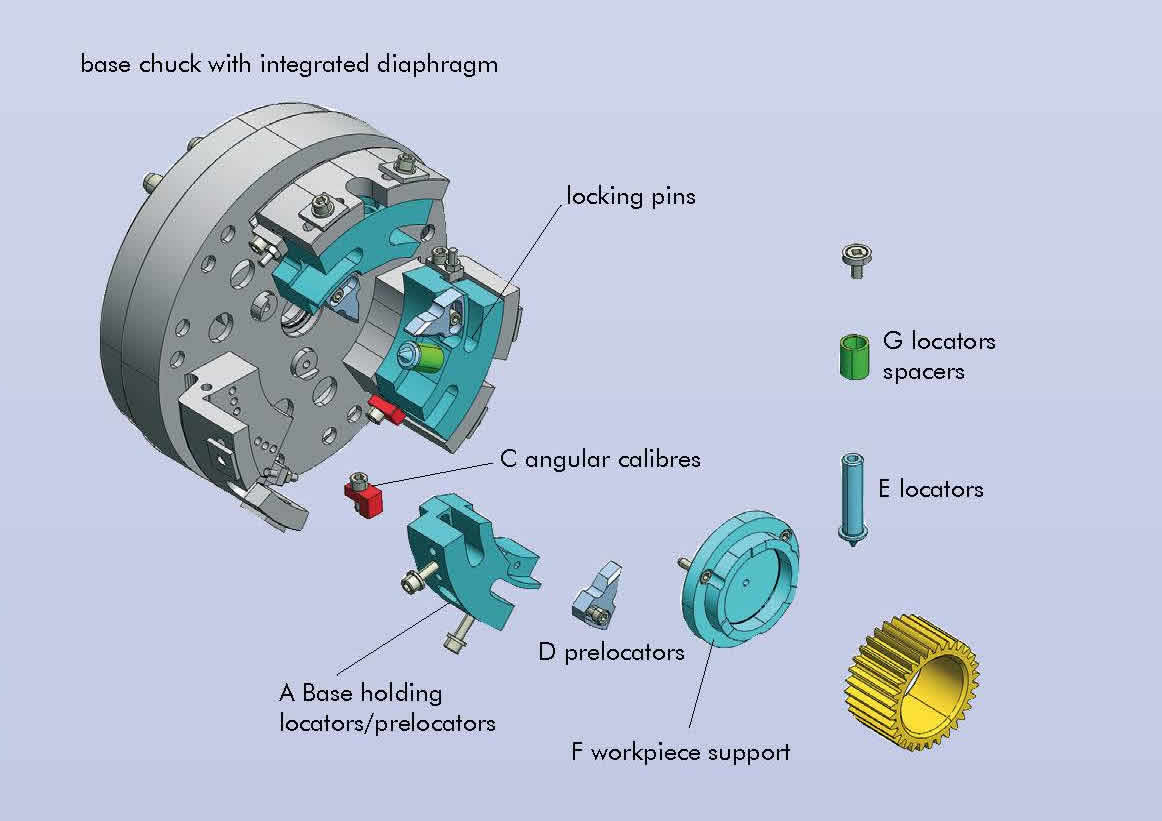

Automatic carrier for gear hole grinding; modular system for small production lots

Absolute modularity by means of angular adjustment of the bases holding locators and prelocators in short time

• Very high repeatability accuracy (within 0.005mm)

• Loading both manual or automatic

• Predisposition for workpiece presence check

• Predisposition for coolant passage

• High accuracy granting a repeatability lower than 0.005mm. The use of presetted angular calibres allows the clamping of a wide range of gears with different teeth No. This always granting a presetting accuracy lower than 0.01mm

• Quick change: long adjustment times of gear to find machine centering are eliminated by using angular calibres which bring the system automatically in position

• Modularity: you can get the desired modularity for clamping different gears with different OD and teeth No just moving the angular bases and replacing locators E and prelocators D locator spacers G and angular calibres C

Outside diameter 215 = Capacity up to 100

Outside diameter 270 = Capacity up to 150

Outside diameter 330 = Capacity up to 200

How it works

When the system is open (loading) the robot or the operator put the gear to be oriented by the prelocators. After the gear is supported against its stop. Driving back the mid shaft by means of the rear rotary cylinder, for the elastic return effect of the carrier body you get the gear clamping through the locators.