News

Discover what is behind the scenes of the production process, between industriousness and wit.

Although mechanic is often associated with static characteristics like precision, reliability, durability, the updating process in which it is involved cannot be overlooked.

The world of tool machines is in fact affected by a constant evolution: keeping up with technological progresses and being able to seize the margins of innovation is the key to the realisation of high-performance product of impeccable quality.

In order to be and stay relevant it is important to get involved: make strategic choices, invest in resources and materials, focus mainly on study, preparation and research, hold the necessary foresight to plan a sustainable development, and last but not least, make productive growth match with ethical soundness.

The real strength of a group, even if it is a corporate group, lays in the sharing of values and goals, that is why in Euroma Group there is no business without ethics: the revenue has to be accompanied by social responsibility and environmental protection.

The aspects that have to be balanced in order to operate in the field of machine tools are therefore numerous, so with great commitment and the always required stability Euroma Groups keeps thinking big, starting from the design to the delivery to the customer.

The production of high-precision, reliable, robust items in not enough. The world of tool machines demands a lot more.

In order to satisfy these needs, the inspiration that lies beneath the creative process is essential, as well as a natural tension towards progress and a strong sense of belonging to keep a vast family united.

Because Euroma Group, in the end, is simply that: one and only family, comprised of various companies, many people and numerous products.

In order to get to know it better, we advise you to watch the latest video: view it now!

News

The processing of bars and pipes following the process of cutting gives a valuable productivity advantage.

The mail goal of every firm that wants to optimize its production is to avoid taking back the piece and moving it around the workshop. The workpiece coming from an automatic machine might be put in a dedicated station placed in line with the process and handled on both sides.

Drillmatic machining spindles, matched with the respective slide units with grinded rolling ball are the ideal solution to every processing of bars and pipes’ ends. The rigidity and the positioning accuracy ensure a high reliability over time. The centring of a piece on a lathe, end-trimming, scarfing, fitted screwing-thread and even more, to achieve an unlimited versatility.

Discover our range of machining spindles and CNC slide units.

News

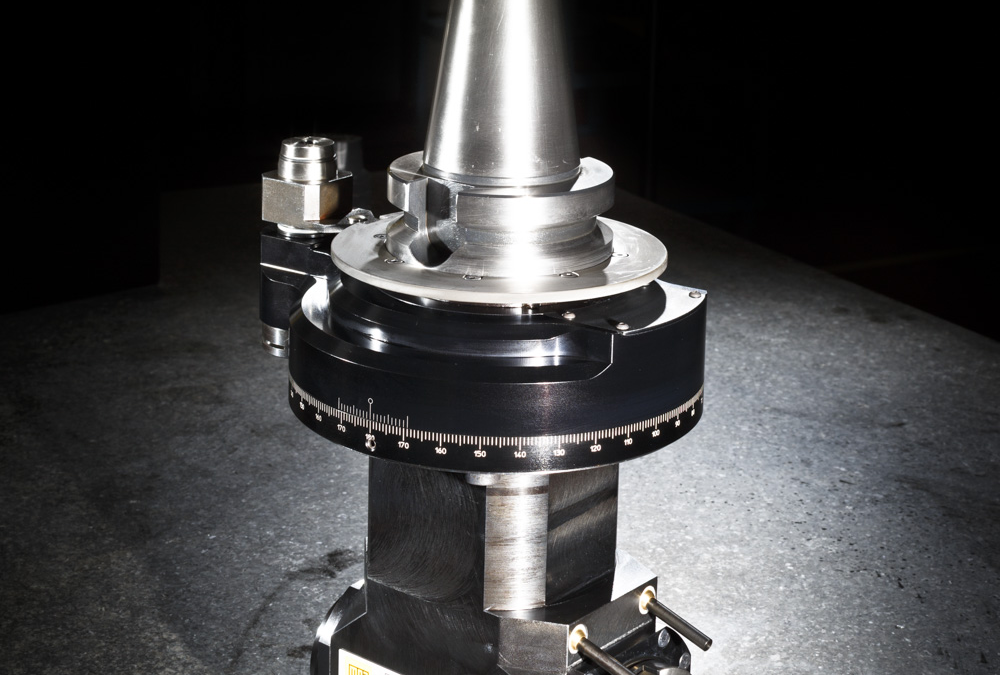

An item becomes an extension of yourself as soon as you forget you are wearing it.

That is what a machining centre provided with MPA angle heads would say, if it could.

In fact, “Slim” Gamma is so slim that it allows the execution of works within small spaces, without ever setting aside an extreme rigidity.

Main technical features here below:

- Integral shank with central shaft in one solid piece.

- Offset design to allow more space for the tool.

- Elastic collet embedded in the head body for the most compact sizes.

- Oblique contact bearings for high cutting speeds

- Small weight and size, suitable for use in tool storage

Download our catalogue and select the most suitable product for your use.

Do not hesitate to contact our technical office.

News

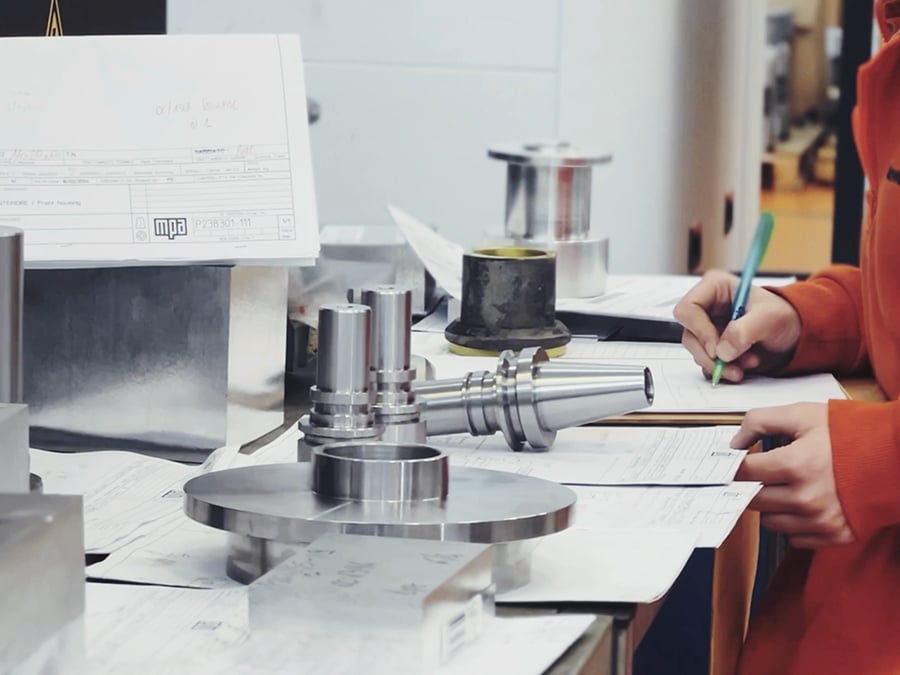

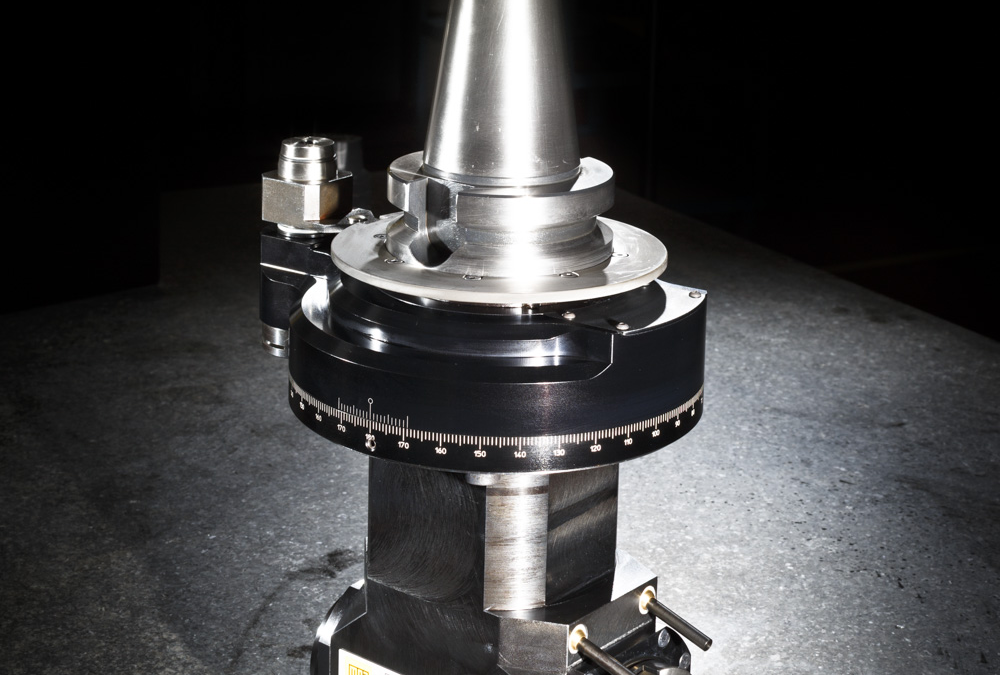

For 45 years we have been increasing the value of your machine tools.

A range that counts more than 130 standard angle heads.

An archive that contains more than 24.000 specialized heads produced for dedicated applications.

With over 45 years’ experience in the world of transfer and traditional machines.

This is MPA.

The time we are in require flexible machine tools, extremely low equipping times, flawless standards and performances.

The wide range of choices that the market offers is surely attractive and full of solutions. But a high-quality machine needs high-quality accessories, and that is where MPA comes into the picture.

MPA is symbol of high quality in the international scene of accessories for machine tools.

Its origins lie in the production of multiple heads with adjustable and fixed centre distance. Later, in the 1980s, with the advent of the first machining centres, MPA focused most of its core business in the design and realisation of a wide range of standard angle heads.

Over time heads have been adapting to the sizes and weights that the market requires, in order to be handled inside tool warehouses, and the variety of it has enlarged thanks to the increasing capacity of the machines to support high-quality and high-performance accessories.

MPA angle heads are available with the classic ISO and HSK shanks of different sizes; every one of them is available with quill clamp, stop-bar pin, anti-rotation system with stiffening pins, passage of the coolant through the tool with low or high pressure, transmission in gear or torque multiplication ratio. Every head undergoes strict quality and size controls before going to the market.

In the catalogue we find “slim” heads, designed to perform small operations in confined spaces, “compact” heads, able to transmit up to 90 Nm torque while maintaining small dimensions, extended heads, angle heads, double-ended heads, off-set heads, heads for heavy duties, adjustable angle heads.

In short, a complete and very wide range of products. Whatever your needs are, our technical staff will be happy to support you towards the best choice.

News

In the beginning, every great success is just a thought

From a sketch on paper to the realization of the complete machine: that is the challenge that Unistand takes up every day. In this case we are talking about a special semi-automatic machine to end-trim and round bars.

The machine is serviced by an infeed chute powered by an operator and can perform four operations in one. This piece, which can be of different diameters and length, is channelled in the engine fixed cradle, where a two-handed pick&place CNC picks it up and brings it to the workstation. After blocking the piece at an adjustable pressure, the hydraulic clamp is moved to the workstation thanks to a controlled axis.

As the bar moves through the two motorized opposite spindles, it gets adequately end-trimmed and then rounded with a special tool, composed of an insert milling cutter and bevel cartridge.

Every axle of the machine is controlled by brushless motors, in order to allow the operator to change format in record time.

The substitution of the tool is extremely quick as well, thanks to the HSK connection, which enables a precise pre-setting, as well as rigidity and high-quality standards of processing.

News

Quill units – Classic and functional design

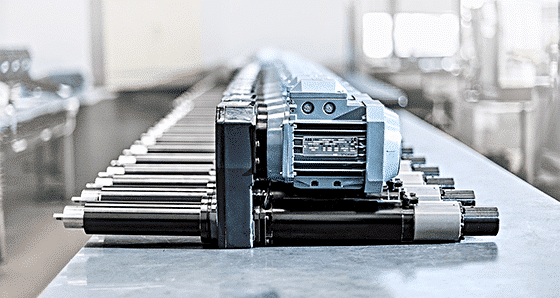

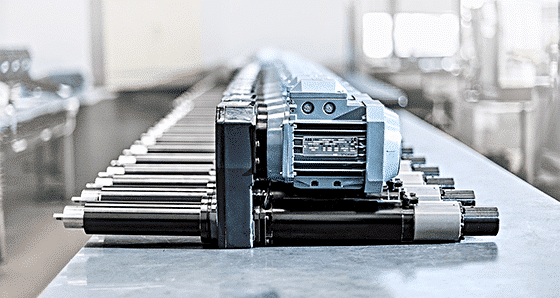

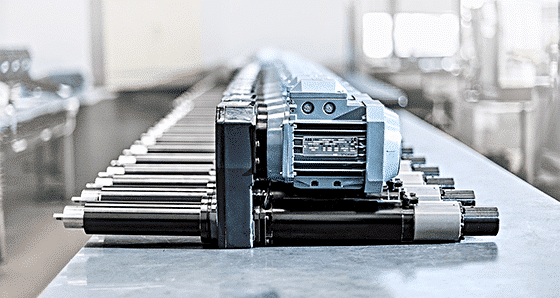

Electro-pneumatic drilling units Drillmatic by Euroma Group are designed to offer the maximum possible modularity.

Manufacturers of industrial machines and automation can have a wide choice and great adaptability in the design.

The different operating stroke solutions, available for most of the quill unit models, maximize space and avoid the designer looking for complex solutions.

The wide range of available tool holders allows not to use extensions and adapters, which distance the tool from the bearings and tend to generate concentricity errors, consequently causing vibrations and poor processing quality.

The well-known and recognizable design of the Quill Electro-pneumatic tapping and drilling units Drillmatic by Euroma Group not only allows an extremely modular fixing, but also offers the great advantage of rotating the unit on 360°, thanks to the static support that “embraces” the cylindrical body of the unit.

The Quill units Drillmatic by Euroma Group can be installed both horizontally and vertically and are available with fixed and adjustable supports for mounting on the machine. Furthermore an angular adjustment is made possible by a 360° articulated support.

Besides all units are equipped with fixing for circular transfer machine, that is with front threaded holes.

Quill tapping units Drillmatic by Euroma Group all have a fixed pneumatic rapid approach stroke as an optional for those obstructions that do not allow to work besides the piece to be machined.

Besides the classic quill drilling and tapping units with lead screw, the range also includes the CNC version, with feed by means of ball screw and brushless motor. This type of quill unit enables to perform any type of axial machining and change the working parameters directly from the operator panel. Drilling with chip discharge cycle, drilling with “skip”, to machine tubes, reverse cycle deburring, interpolated tapping: all of these options are easily manageable as the CNC Drillmatic by Euroma Group Quill units are ideally suited to perform them.

Our staff is at your complete disposal for any inquiry, so do not hesitate to contact us.