News

The new way of producing: process control, remote management, instant format change

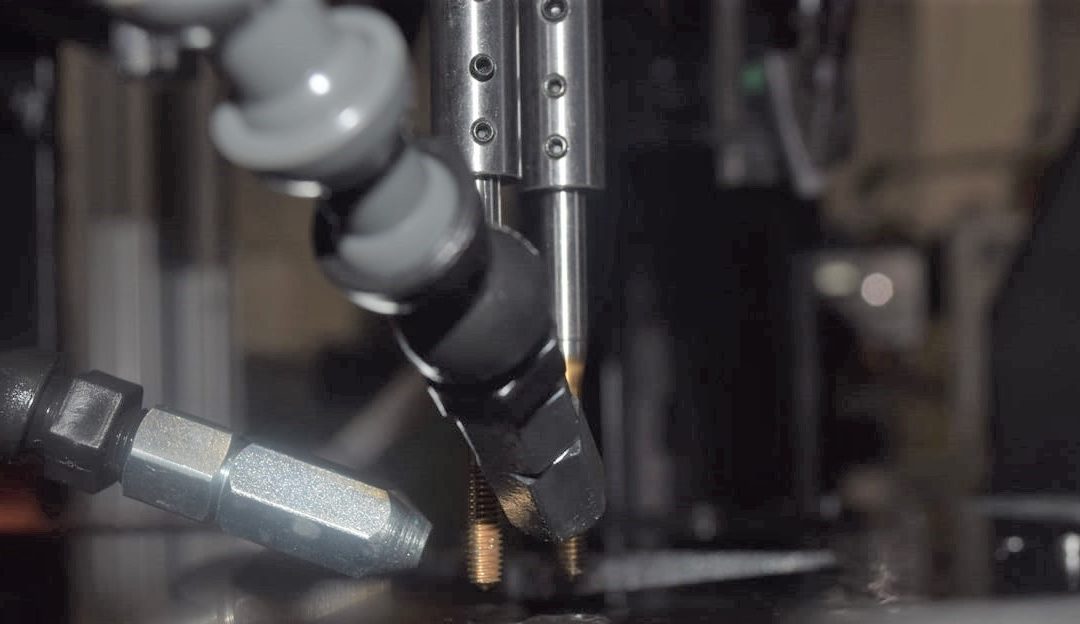

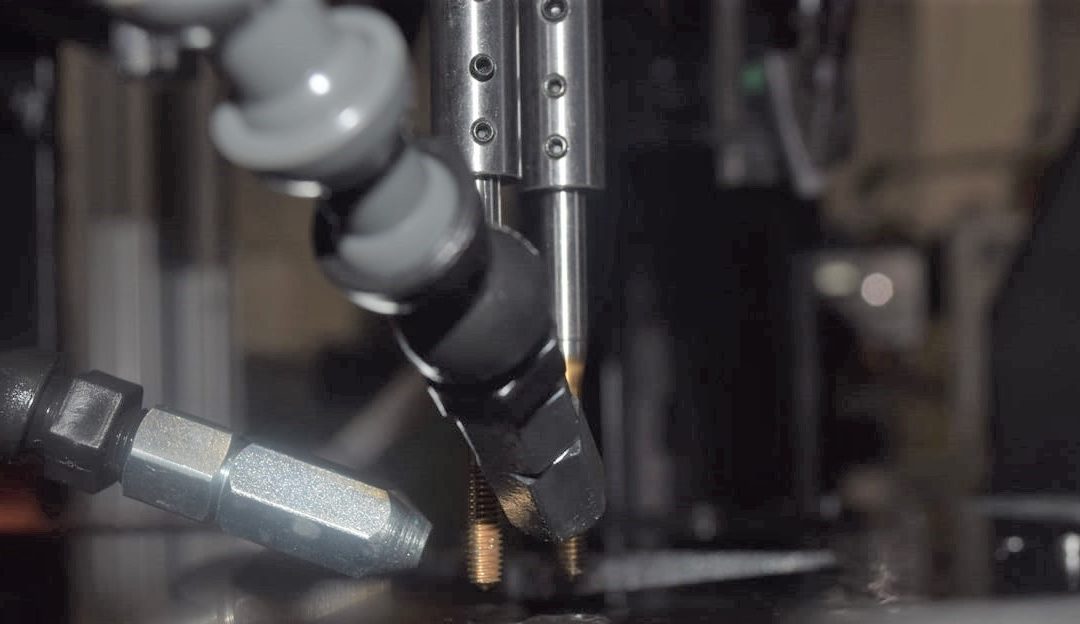

Transfer with high drilling and roll threading production on metal small parts: Let’s discover all particular features of the transfer machine together with the concept of today’s productivity.

The wheel is turning and turning…

The transfer machine for the production of metal small parts always has to meet all necessary speed, precision, reliability and consistency standards.

But today this isn’t enough: Since human tendency is to go for an even less manual work, the machine needs to be even more independent from operator’s control.

4.0 Industry is the big movie screen where all values, tendencies and diagrams are outlined and made explicit. But, what hides behind it? What is faster than the electricity passing from the control devices to the PLC terminal boards?

The answer to these questions is only one: the innovation willingness.

This is actually the industry sector which is changing and adapting.

Euroma Group took the hard challenge to put its signature on a machine that doesn’t produce only metal small parts every 3 seconds, but that is also able to make two opposite concepts coexist: rigor and flexibility.

From one side, we talk about rigor because each machine’s action is controlled. In fact, all pieces undergo process controls that provide the remote machine supervision with a clear and detailed overview, which, however, doesn’t affect significantly the machine’s flexibility.

For the other side, we talk about flexibility because the format change is extremely fast and easy to handle. In fact,

thanks to the logic in which this machine was conceived, it’s possible to switch from one piece to the other in 30 minutes.

Our staff is at your complete disposal for any further information.

News

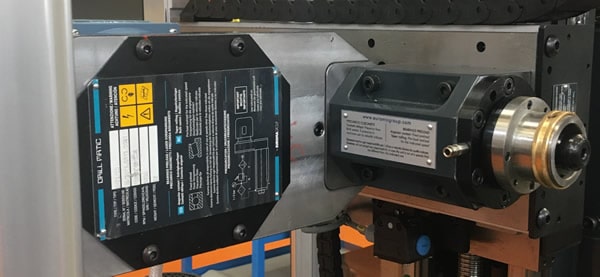

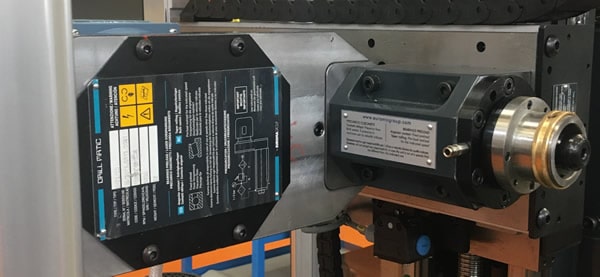

Euroma Group would like to thank MPA for having accepted to take part in a common project aimed at aggregating different historic brands from the machine tool components sector under a single purpose which combines experience and development.

Therefore, it’s with great satisfaction that today our Group can count on the Made in Italy excellence of MPA that has been producing angular heads, multi spindle heads and overgears since more than 45 years.

This collaboration is due to common ethical and entrepreneurial values and to the awareness of preserving brand’s identity together with its personnel and its traditions. In fact, the preservation of all single identities and members is essential for a company.

Therefore, Euroma Group is enthusiastic about taking the chance to cooperate with MPA, knowing that their mutual exchange will enrich all members of the Group.

Following this important goal, in the next future, we hope to enlarge our Group with all Italian brands, whose solution for future challenges is a “combination of important dimension and common ideas”.

News

It is commonly known that automation, arises from the need to produce a high number of pieces in a short time and mostly with a level of repeatability and tolerance close to perfection.

Human supervision, according to the new philosophy, has to be so significantly reduced that the word "operator" is now only a legacy of the past, since the job of those who hold that role is no longer to operate but “to control”

However, nowadays there are only few sectors that are still lucky enough to have large numbers of parts to be scheduled in production. After the crisis that begun more than a decade ago, there has been a sequence of ups and downs mixed with promises and hints of confidence, forecasts, and hypotheses of trends. However, we haven’t a returned to full production yet.

Automation has adapted and has evolved from being rigid and heavy to being flexible and "minimal". Cast iron bases have turned into aluminum profiles, oil tanks have given way to MQL systems, therefore spaces have necessarily shrunk. Evolution and adaptation in the world of industrialization are generated by the same needs as the evolution of people and follow the same key points of human adaptation to conditions of majeure force. In this case, we also speak about species’ survival and origins’ conservation. In order not to die and not to be invaded, the silent and laborious world made by all that group of small-medium craftsmen and inventors has shaped its ideas over the time to serve something bigger and longer lasting than themselves.

There must be four prerogatives: quality, savings, autonomy and flexibility. The new machine concept must embrace all these concepts and mix them to form something attractive for the market. It must be something that has a value that justifies the purchase and makes it less tragic to predict that an article will change shape in the future, that a center distance will move or that, in the worst cases, will go out of production.

This can happen in any sector because everything evolves. Cars are constantly changing (laws and governments encourage this change, perhaps as an attempt to keep consumerism alive), engines are designed differently, materials change not only in the metalworking sector but also in the appliance and building sector and the list could go on forever.

Especially in the latter case, above all in the production of accessories for windows, components changes are on the agenda. The competition, perhaps among the highest ever, is so high to lead to the implementation of the research aimed at improving and optimizing production costs. Die-cast zamak or cold-pressed steel parts need to be picked up mostly with drilling, threading and screwing operations. The biggest problem for those who produce in this sector is the great variety of components that have similar shape but with significant geometric differences, due to which it isn’t possible combine different pieces in the same production cycle which is therefore defined as “rigid”. This is the reason why the idea of a special machine has been developed , which is consequently rigid by its intrinsic nature but also flexible and quick in format change. Luckily, in the world of aluminum frames, large numbers, even though fragmented, are still there, but each component doesn’t employ a single machine. To make ends meet, therefore, it is necessary to use a single machine which makes it possible to perform a format change quickly, intelligently and can be handled even by an inexperienced operator.

Which are the limits? Those we impose on ourselves. Theoretically, with a machine designed to be flexible, we can work any type of piece and all similar ones. It’s only necessary to establish the number of stations at the start, the structural capabilities of each individual station (power, torque, number of revolutions, etc …)the cycle time and the quality to be reached. Everything else is design.

The replacement of various components to perform the format change is an operation of limited duration, and varies according to the piece to be produced. The operator is facilitated in the operation by fixed references that leave no room for tooling errors.

Once the machine has been equipped for the new production, it is sufficient to recall the piece to be machined from the touch screen. The possibility to use the 4.0 interface also helps the operator by indicating him which the next format changes will be so that the fitter can prepare the components to be replaced in advance.

This machine concept can be applied to any production sector. For any need or evaluation, Euroma Group is at your complete disposal. We’ll be happy to deal with any type of request to give you the most effective solution to your production needs.

News

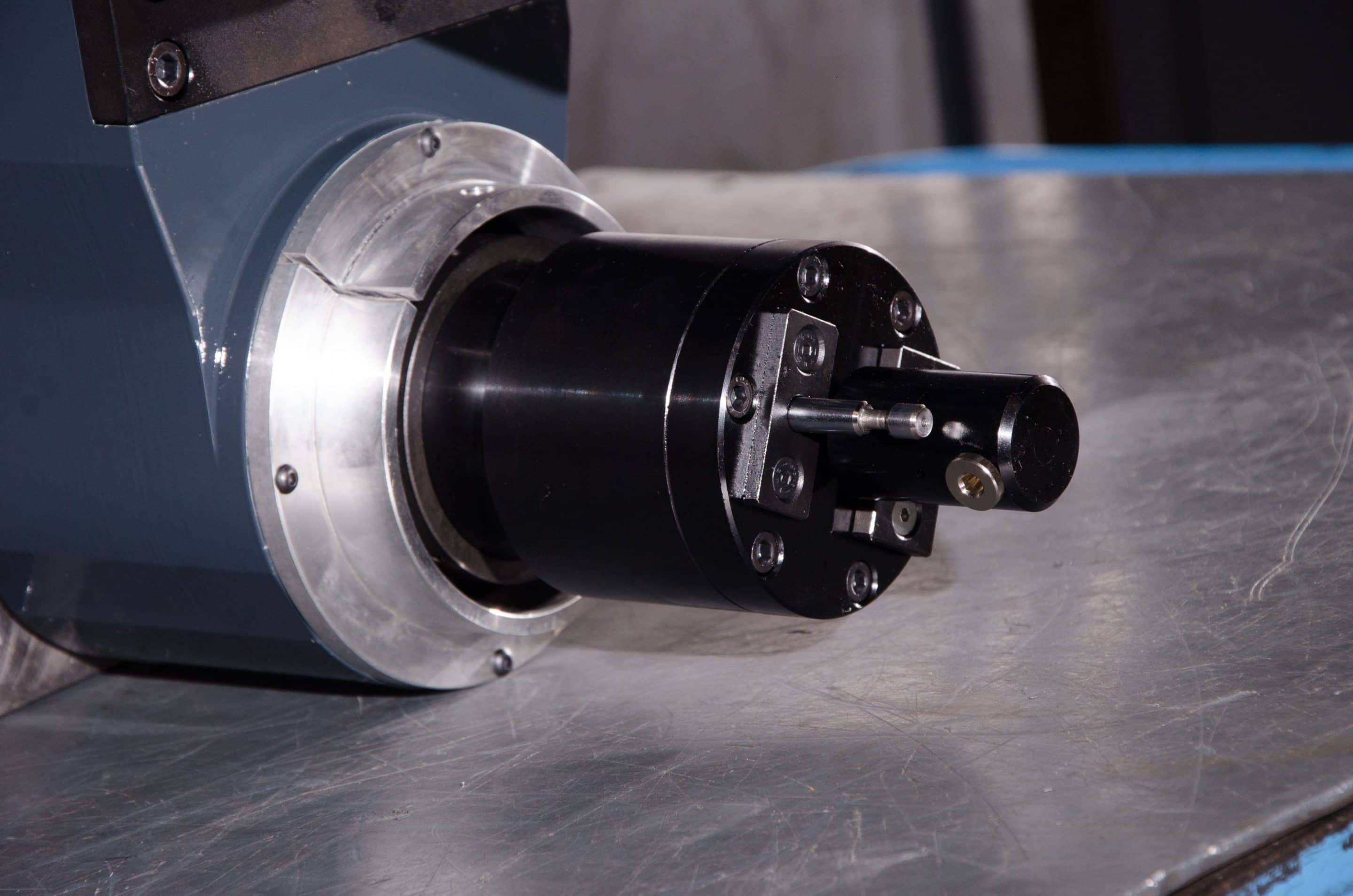

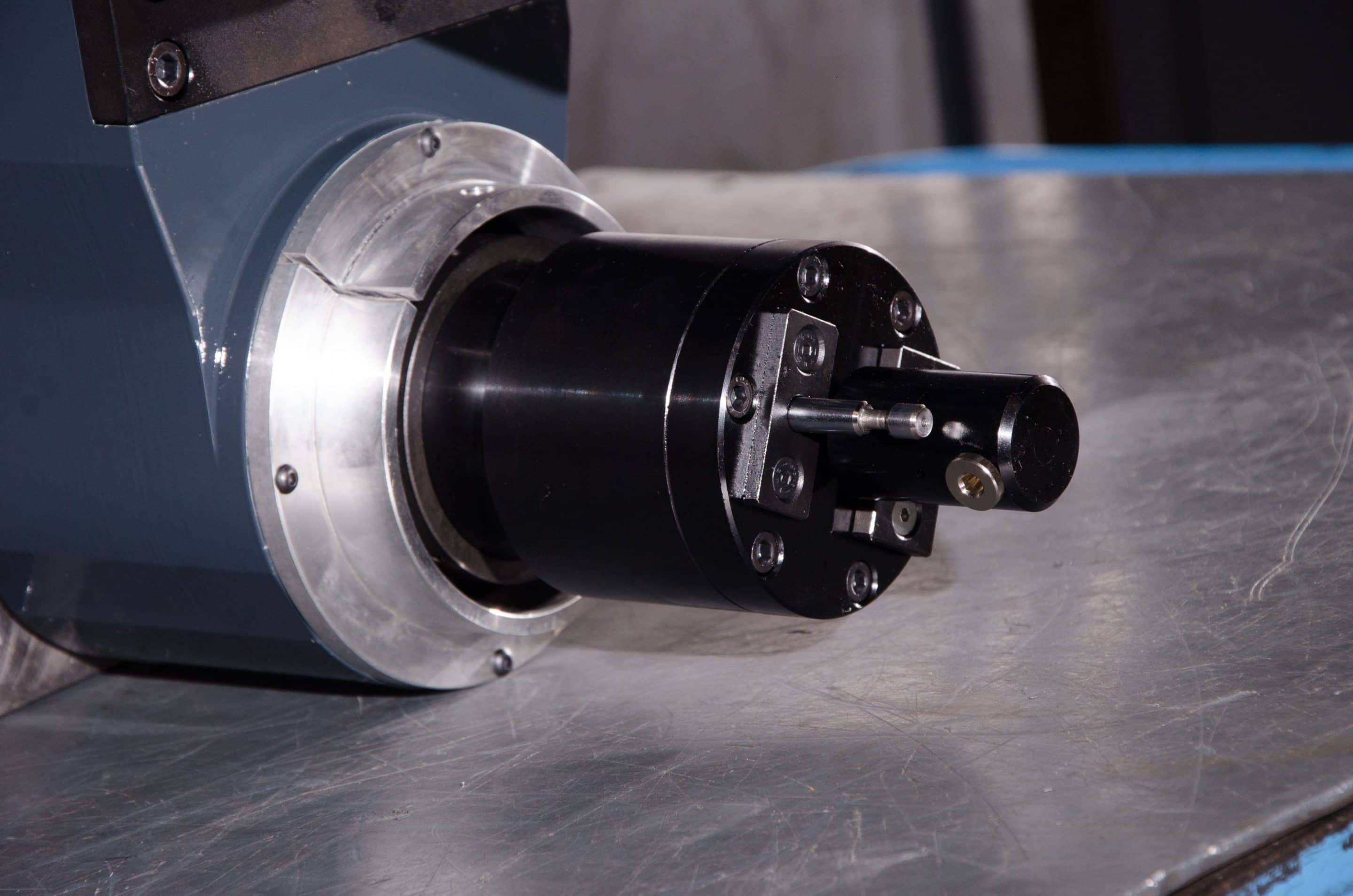

Today, the implementation of the product, strongly requested by the Market, makes it possible to set up even the smallest motorized spindle size with HSK shafts, which give the operator the possibility to perform a tool change and a presetting outside the machine with extreme precision and speed.

Taking advantage of both the taper and the stop of the tool holder on the face of the female cone, the HSK connection guarantees great rigidity during machining, both for drilling and threading but also and above all for milling that involves important radial efforts.

The rigidity then translates into the possibility of having high rotation speeds at extremely reduced concentricity, better performances and ever lower cycle times.

Besides, thanks to the extreme ease for the operator to perform the manual unclamping of the shank, the HSK system is strongly recommended for all those applications where the maintenance operations and the accesses inside the machinery are limited due to the reduced space or where the spindle is mounted in vertical position.

In fact, compared with the version with pull stud for ISO shank, where the use of two wrenches is necessary, the operator doesn’t need to support the shank to prevent it from falling, since it’s sufficient to use an Allen key and thereby to have the possibility of holding the shank with hands.

Like for the ISO version, the passage of the coolant through the spindle with adduction from the rear rotary joint is available. Moreover, our staff is always available to help with any type of request.

News

Same concept, new design,

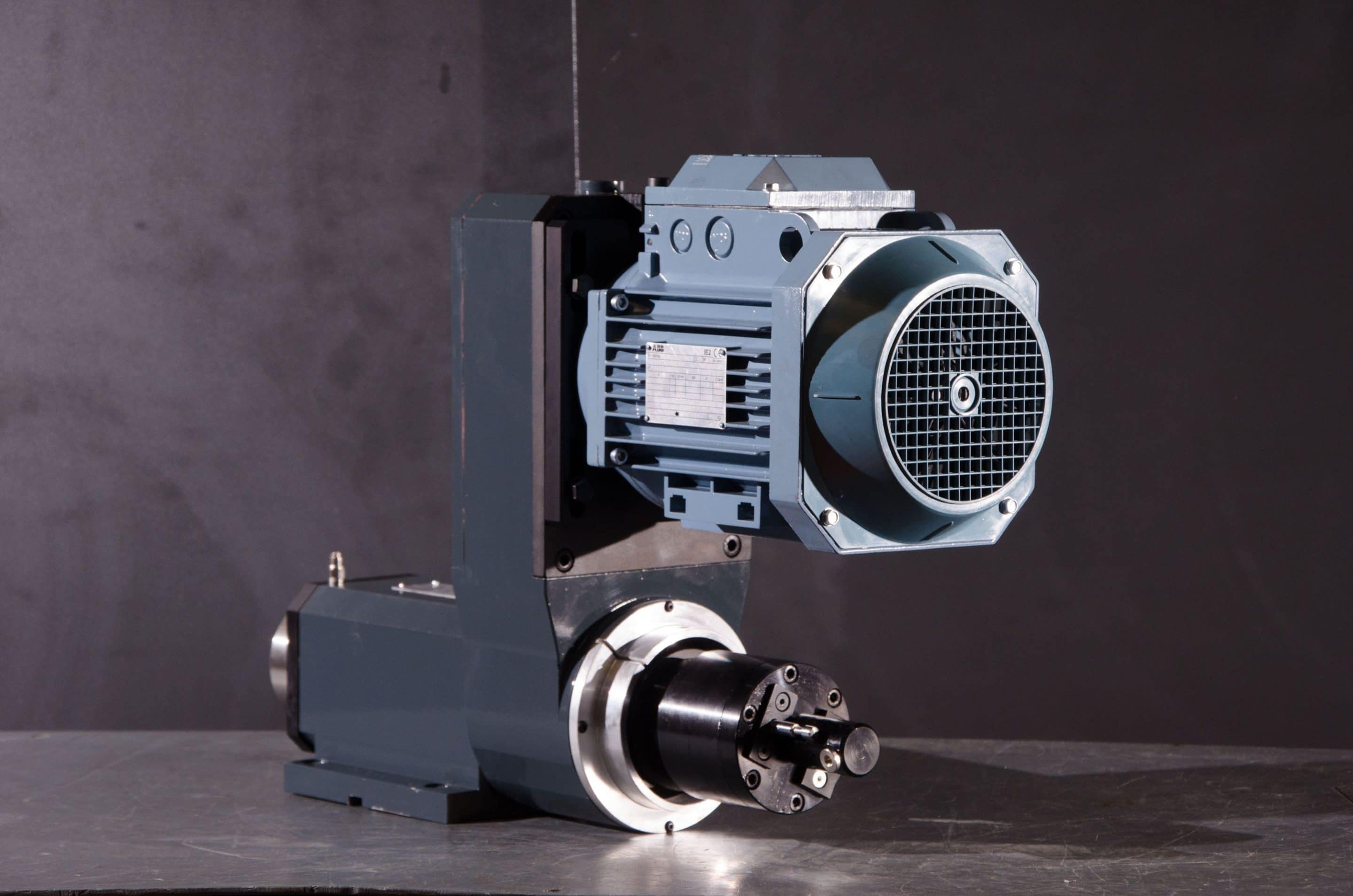

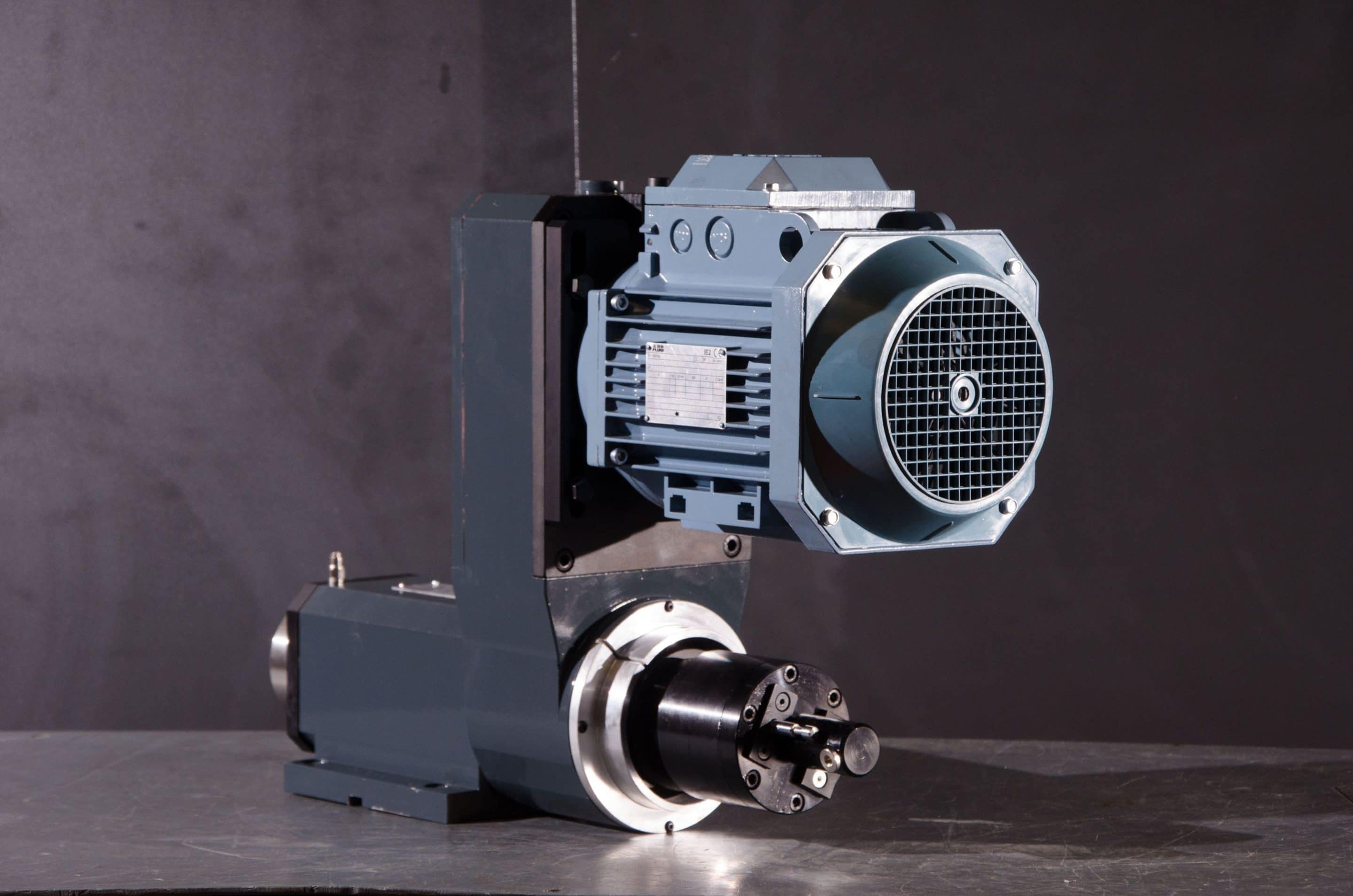

EUROMA motorized spindles equipped with an automatic tool change system have a new look and are dedicated mostly to the gantry machine sector.

To be precise, we are talking about sheet metal working machines, which is plasma cutting, laser cutting and oxy-fuel cutting.

Besides sheet metal laser cutting, obtained with the above mentioned, performing mechanical precision operations – such as drilling and threading – within the process is now an usual thing. Nowadays, it would be unthinkable to bring the chip removalprocess out of the machine and move the piece in several stages. For most of the world’s largest gantry machine manufacturers, the old concept of the revolver head, currently limited in its power and torque transmitted capabilities, is being abandoned to leave more and more space for the use of the motorized spindles, CNC feed with automatic tool change system and tool rack. This concept is very similar to that of machining centers.

In fact, EUROMA motorized spindles offer great strength, reliability and precision. Furthermore, the new design, developed especially for the needs of this type of machine, further enhances its features.

What has most significantly improved is the dimensional development of the pneumatic tool change system which is extremely compact if compared with the previous one, with a diameter of only 150 mm. The single-acting cylinder generates an unlocking thrust to the plate springs of 14000N in the ISO40 version, while for mechanical retention the pulling force reaches 18000N thanks to the thrust multiplier.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

There’s also a fourth sensor mounted on the rear part of the cylinder, which reads the actual return, thus ensuring the mechanical pull of the springs. The fifth sensor is mounted directly on the shaft and reads its rotation to

manage the timing of the two ISO dowels.

The extended spindle shaft makes it possible to reduce the working strokes to a minimum, thus avoiding any space problem usually due to the transmission casings and the motors that are applied. Nowadays, the range has 3 spindle sizes (DX28 – DX38 – DX58) with the possibility to choose between ISO40 and ISO50 shank.

The spindles with this new system are perfectly suitable with the EX model feed slides, which can be used to perform the working strokes with ball screw and CNC motor. If you need more information, please do not hesitate to contact us!

News

Reach every corner of the world with our products is the challenge we have set ourselves

In the era of Industry 4.0 we can afford ideas and concepts that until just few years ago were almost prohibitive and which are now commonplace. But technology alone cannot do anything, if you do not even have a professional and technical presence on the market.

EuromaGroup has a widespread presence throughout the global territory through its dealers, but is proud to dispose of and make available to its customers an highly experienced technical sales representative.. And with this occasion we are pleased to introduce you Beatrice Avanzini.

Beatrice Avanzini is our worldwide interface for all three macro categories of Euroma Group products.

Specifically, Beatrice Avanzini is your direct contact for:

Drillmatic in Russia, China and the United States

CMT all over the world

ISA all over the world

If the mountain won’t come to Mohammed….

For any request or technical/commercial information please contact us!

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.

The tool change system is also equipped with 5 sensors that manage spindle safety logic system. In fact, it’s possible to know the position of the pull stud thanks to the three sensors mounted on the back of the unit.